TM 5-822-11/AFP 88-6, Chap. 7

sealant to fail prematurely in the same manner as

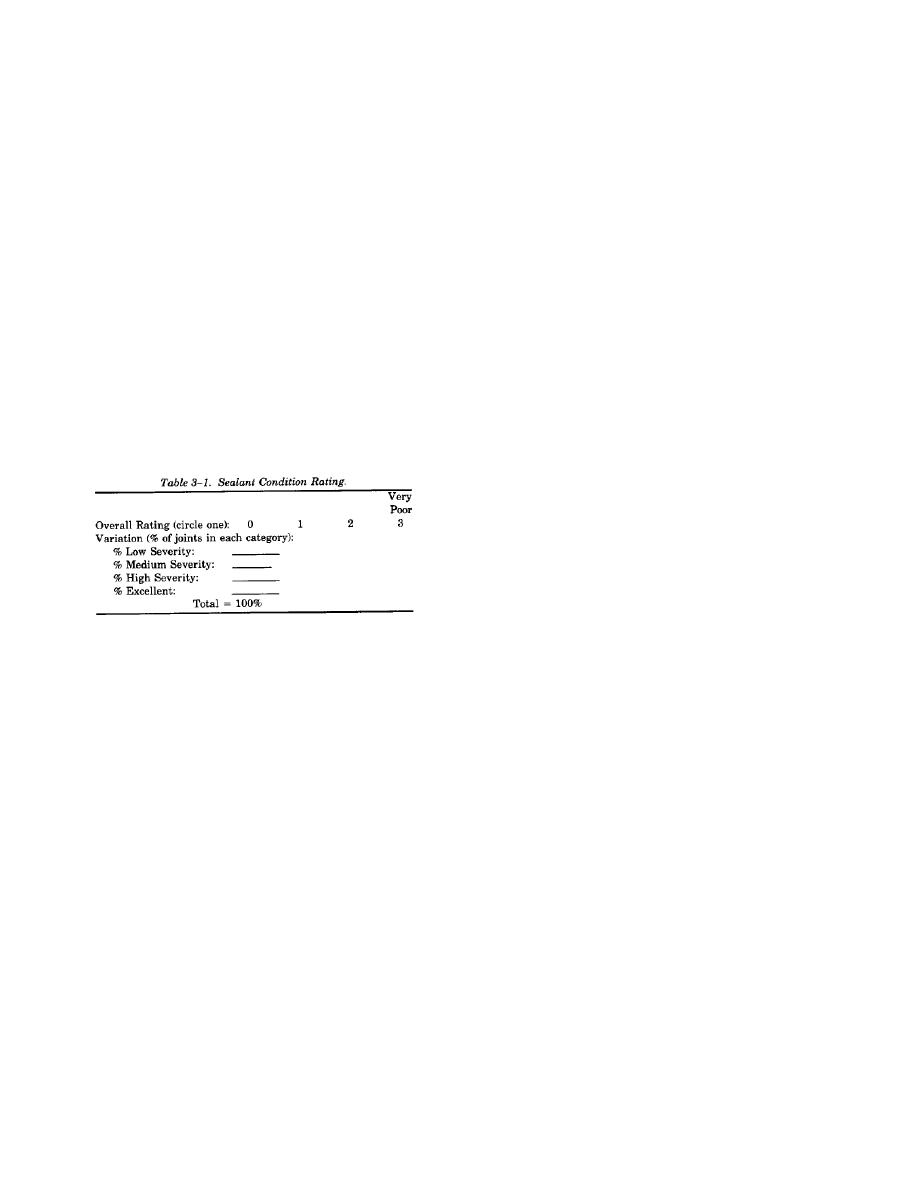

table 3-1, to show the overall condition of the

the previous sealant. Examples of possible causes

joint sealant. The relative amounts of each level of

of premature sealant failure may include but are

severity present can be recorded to show the

not limited to incorrect sealant reservoir shape

variability of the joint seal damage.

factors, excessive vertical movement or too large

c. Determine Joint or Crack Condition. The

of a working range at the joint, and improper

condition of the joints or cracks is recorded as the

sealing techniques used during sealant installation.

percentage of slabs with the specified severity of

spalling. The data for severity of spalling are used

3-3. Condition Survey.

to determine the existing pavement condition. The

a. The pavement must be surveyed according to

general condition of the pavement feature being

the procedures in TM 5-826-6/AFR 93-5 to deter-

evaluated and the secondary factors of environ-

mine the current condition of the sealant, the joint

ment and soil type which influence joint sealant

and crack condition, moisture related distress

performance must be recorded. The data provide

types, and the overall pavement condition. Field

the information needed to evaluate sealant needs

measurements may be required to determine the

and function. Historical data and future use are

existing joint shape factor. The measurements

recorded to provide an indication of past perfor-

should be made during the condition survey by

mance and future requirements of the sealant and

physically removing some of the old sealant and

feature. The data collected can be presented on the

recording its shape and hardness. Tables 3-1 and

pavement evaluation checklist shown in table 3-2.

3-2 contain the items that should be collected to

3-4. Evaluation to Justify Sealing

allow evaluation of the sealant and pavement.

Work. After the survey data and other factors

affecting sealant performance have been collected,

it must be evaluated. The results from the analysis

will determine if resealing is justified. The

checklists shown in tables 3-1 and 3-2 provide the

step-by-step approach to the evaluation. The fol-

lowing guidelines indicate the relative need to seal

a given pavement based upon the ratings obtained

from the checklists. The overall sealant ratings are

given in the following paragraphs.

a. Excellent to Very Good (0 to 1). Resealing

b. Determining Sealant Condition. The proce-

is not required. Some routine sealing may be

dures in TM 5-826-6/AFR 93-5 rate the average

needed in localized areas of high-severity damage.

joint condition within each sample unit at a low-,

medium-, or high-severity level. A more accurate

b. Good to Fair (1 to 2). Resealing can be

but more time-consuming method would be to rate

considered. Any of the following items would

the sealant condition in each joint as the survey is

indicate that remedial action should be considered

conducted. In either case, the overall joint sealant

to prevent the distress from progressing.

condition rating may be calculated using the fol-

(1) A moisture susceptible subgrade and an-

lowing equation:

nual rainfall of more than 15 inches or a monthly

rainfall of more than 3 inches.

Rating = [(%L)(1.0) + (%M)(2.0) + (%H)(3.0)]/100.0

(2) More than 10 percent of the slabs with

where

medium or high-severity joint and corner spalls.

%L

= percent of sample units having low severity joint

(3) Evidence of incompressibles in the joints.

seal damage or percent of total length having low

(4) More than 10 percent of the slabs with

severity joint seal damage.

medium or high-severity faulting.

%M

=

percent of sample units having medium severity

(5) More than 30 percent of the deduct values

joint seal damage or percent of total joint length

caused by moisture accelerated distress types.

having medium severity joint seal damage.

(6) Significant or potential FOD problems

%H

=

percent of sample units having high severity joint

due to spalling joints or cracks have developed.

seal damage or percent of total joint length having

(7) More than 30 percent of the joint sealant

high severity joint seal damage.

damage is at a high-severity level.

The equation produces a rating from 0 to 3 that

(8) The change in the PCI when calculated

indicates the general condition and can be pre-

assuming no joint seal damage present is signifi-

sented on a condition rating scale, as shown in

cant.

3-3

Previous Page

Previous Page