TM 5-822-11/AFP 88-6, Chap. 7

(2) Improper web design can produce a

To maintain adequate adhesion and to reduce the

vertical component to the web stress which is

internal strains of a sealant, a shape factor

known as vertical stress. If this stress is not

between 1.0 and 1.5 is recommended (1.0#S#1.5,

balanced, the seal can work itself out of or deeper

where S = DJW) for most field-poured sealants.

into the joint as the joint opens and closes.

Some single-component cold-applied sealants

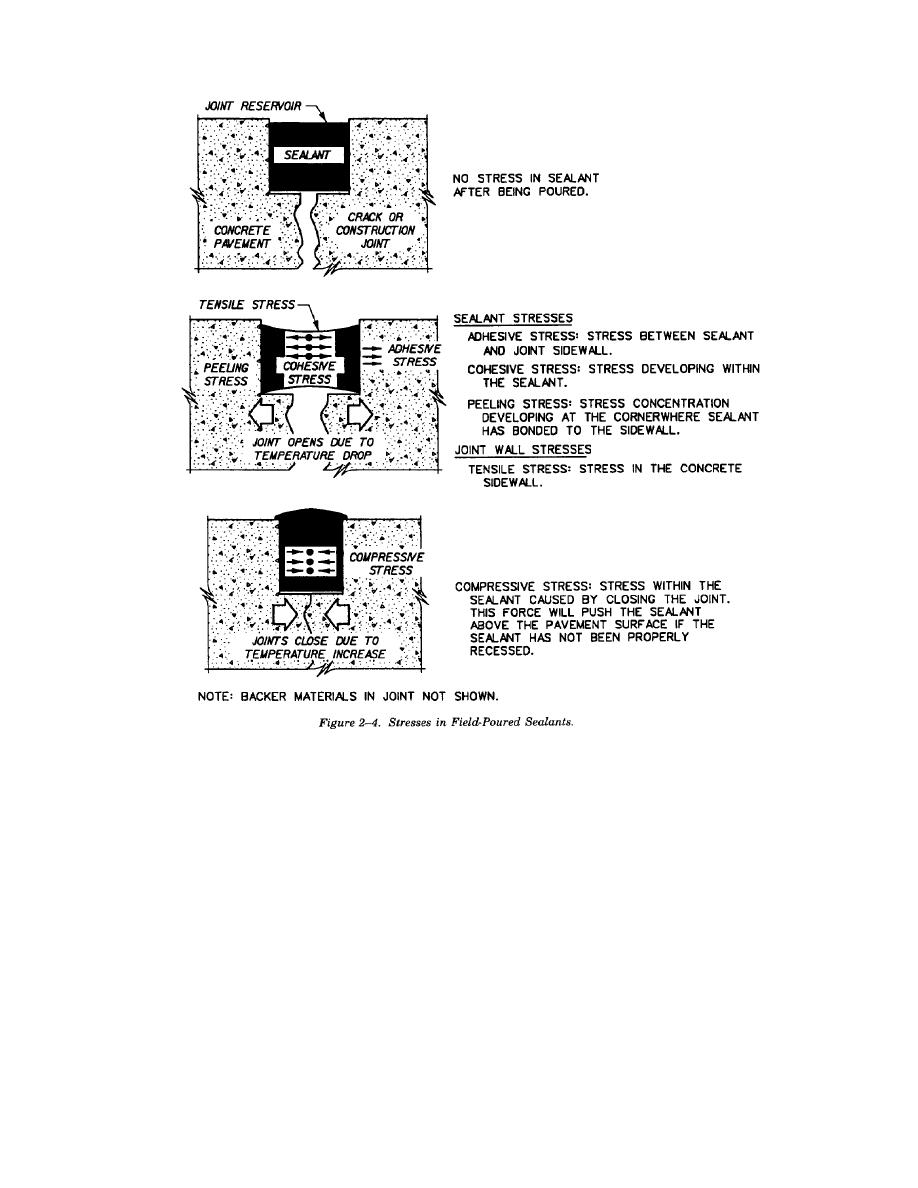

c. As joints open and close, field.poured

require a shape factor of less than 1 to perform

sealants change in shape but not in volume.

properly; therefore, particular care in designing

Therefore, the stresses that occur are primarily a

the joints and selecting the depth to install backer

function of the shape of the sealant at the time it is

material should be taken when these materials are

poured. The shape of the field-poured sealant is

used. The shape factor of the preformed

expressed in terms of the depth (D) to width (W)

compression seal is determined by the

ratio as shown in figure 2-1. The depth to width

manufacturer.

ratio (DJW) is known as the shape factor.

d. The depth of a field-poured sealant can be

Providing a small shape factor, small depth versus

controlled by the use of a backer material if the

a large width for an in-place sealant generally

joint reservoir depth is deeper than the depth

reduces the internal strains, hence improving the

required to maintain the proper shape factor. The

elasticity of the field-poured sealant. However, a

backer material helps support the sealant during

relatively large sealant depth is desirable to ensure

curing and prevents sagging of the sealant into the

adequate bonding of the sealant to the joint face.

lower portion of the joint. The backer material

2-8

Previous Page

Previous Page