UFC 3-250-03

15 May 2001

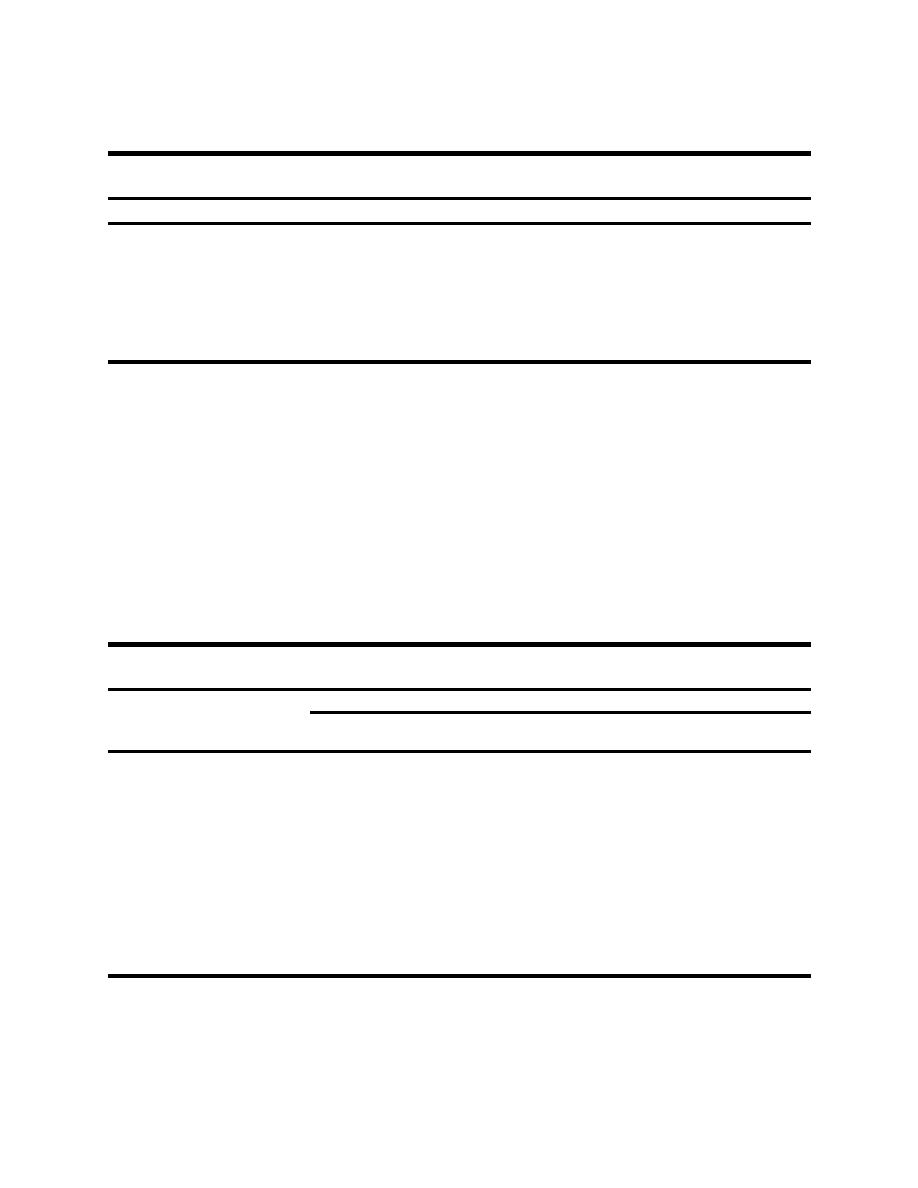

Table B-1

Determination of Optimum Asphalt Content

Selection Point

Asphalt Emulsion Added

Peak of stability curve

0.5 percent

Peak of unit-weight curve

1.0 percent

4 percent voids in total mix

1.0 percent

75 percent total voids filled with asphalt

0.0 percent

Average

0.6 percent

B-2. HOT-MIX RECYCLING PROBLEM. The middle 24 meters (75 feet) of a runway is to be removed

full depth (7.5 centimeters, 3 inches) and replaced with a recycled asphalt mixture containing 50 percent

reclaimed asphalt pavement. Develop the design mix.

a. Step 1. Obtain samples of the in-place pavement (use jackhammer or other acceptable means)

along with samples of the new aggregates to be used and the new asphalt and recycled agent, if

needed.

b. Step 2. Run sieve analyses on all aggregates including aggregate extracted from sample of the

in-place asphalt mixture. If an adequate history upon which to evaluate the new aggregate is not

available, use the standard tests as outlined in TM 5-822-8/AFM 88-6, Chap. 8 (Future AFJMAN 32-

1028), and TM 5-825-2/AFJMAN 32-1014. The history of the performance of the old aggregate should

suffice for its evaluation. The aggregate gradations for this example are shown in table B-2.

Table B-2

Aggregate Gradations

Percent Passing

Reclaimed Asphalt

New Coarse

New Fine

New Natural

Sieve Size

Pavement

Aggregate

Aggregate

Sand

19 mm (3/4 inch)

100

100

100

100

12.7 mm (1/2 inch)

95

95

100

100

9.5 mm (3/8 inch)

83

75

100

100

4.75 mm (No. 4)

63

12

100

98

2.36 mm (No. 8)

52

2

79

95

1.18 mm (No. 16)

40

0

57

89

600 Fm (No. 30)

29

0

42

77

300 Fm (No. 50)

21

0

30

48

150 Fm (No. 100)

12

0

18

12

75 Fm (No. 200)

6.0

0

8.0

4.5

B-2

Previous Page

Previous Page