UFC 3-250-03

15 May 2001

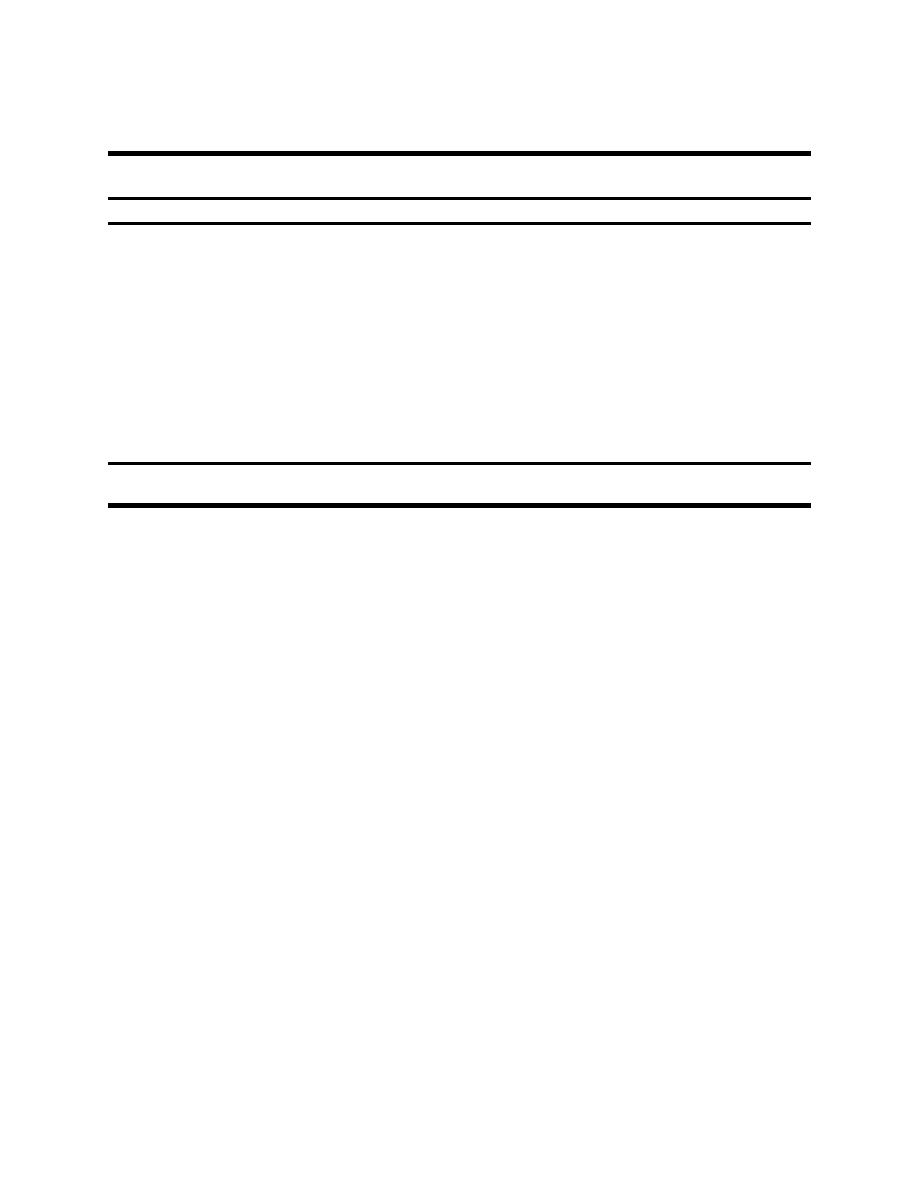

Table 6-8

Mixing Temperatures for Asphalt Materials

Temperature Range,EF

Bituminous Material Type

Grade

Emulsified asphalts

MS-2

100-160

MS-2h

100-160

SS-1

75-130

SS-1h

75-130

Cut-back asphalts

RC-70

100-135

RC-250

135-175

RC-800

170-205

MC-70

100-135

MC-250

135-175

MC-800

170-205

Note: MC = medium curing; RC = rapid curing; MS = medium set; and SS = slow set.

(7) Adjusting mix proportions. Mix proportions shall be adjusted whenever tests indicate that

specified tolerances are not being met. Fully automated plants should produce consistent mixtures,

provided they are correctly calibrated and in good working condition. Improper weighing or faulty scales

may be detected readily and corrective measures taken by maintaining a close check or load weights.

The total weight of each load of mixture produced shall not vary more than plus or minus 2 percent from

the total of the batch weights dumped into the truck. Figure 2-15 presents other probable causes of

paving-mixture deficiencies due to improper plant operations.

e. Preparation of construction specifications.

(1) Specifications. Cold-laid asphalt mixtures will be produced according to provisions of guide

specifications except when small quantities of mix, less than 100 metric tons, may be necessary for

limited use in repairs. In these cases, the procedures specified in the guide specification would not be

economical. When such an exception is deemed necessary, locally available cold-laid bituminous mix

produced according to local state highway department specifications may be used when approved by

the Division Engineer. When the quality exceeds 100 metric tons for Army projects, approval from the

USACE Transportation Systems Center (CENWO-ED-TX) will be required. A copy of the specification or

proper reference thereto and information regarding traffic conditions and facilities to be paved will

accompany the request for approval.

(2) Placing. Although closer control of layer thickness and better prevention of segregation of

the mix can be achieved with a mechanical spreader, a motor grader is sometimes desirable for

spreading plant-mix cold-laid pavements. Aeration of the mix to remove some of the volatile material is

often necessary to bring the mix to the proper condition for compaction. A motor grader can aerate the

mix by balding it back and forth across the roadbed.

(3) Compaction of mixture. At the time of compaction, the asphalt material in the mixture must

provide a proper amount of cohesion, so that the desired density can be reached. Cohesion of the

mixture will be controlled by the type of asphalt material, volatile content, and temperature of the

mixture. Low cohesion will cause the mix to be unstable under the roller, while high cohesion will cause

6-9

Previous Page

Previous Page