TM 5-822-5/AFM 88-7, Chap. 1

equal dimensions under traffic. Therefore, it is

desirable, insofar as practicable, to keep the length

and width dimensions as nearly equal as possible. In

no case should the length dimension (in the

direction of paving) exceed the width dimension

more than 25 percent. Where it is desired to exceed

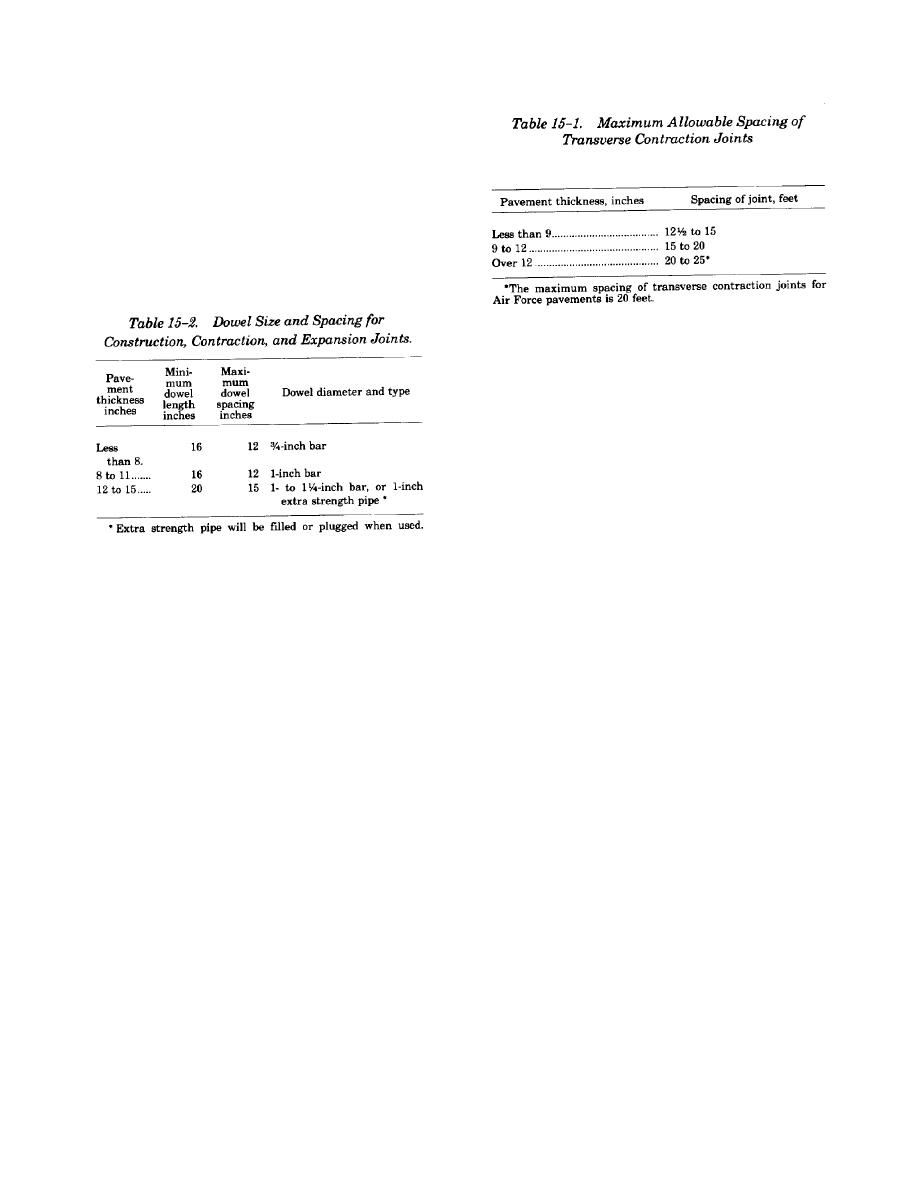

the joint spacing (in table 15-1), a request must be

submitted to HQUSACE (CEMP-ET) or the

appropriate Air Force Major Command outlining

local conditions that indicate that the proposed

change in joint spacing is desirable.

(b) For plain concrete pavements,

deformed tie bars will be required in longitudinal

contraction joints that fall 15 feet or less from the

free edge of paved areas that are 100 feet or greater

in width. The deformed tie bars will be e inch in di-

ameter, 30 inches long, and spaced on 30-inch cen-

ters. In addition, longitudinal contraction joints

placed along the center line of paving lanes that

have a width greater than the maximum spacing of

transverse contraction joints will be tied using tie

bars of the above-mentioned dimensions (fig 15-3).

b. Construction joints. Construction joints may

(4) Spacing of longitudinal contraction

be required in both the longitudinal and trans-verse

joints. Contraction joints will be placed along the

directions. Longitudinal construction joints,

center line of paving lanes that have a width greater

generally spaced 20 to 25 feet apart but which may

than the determined maximum spacing of trans-

reach 50 feet apart, depending on construction

verse contraction joints in table 15-1. These joints

equipment capability, will be provided to separate

may also be required in the longitudinal direction

successively placed paving lanes. Transverse con-

for overlays, regardless of overlay thickness, to

struction joints will be installed at the end of each

match joints existing in the base pavement unless a

day's paving operation, and at other points within a

bond-breaking medium is used between the overlay

paving lane where the placing of concrete is dis-

and base pavement or the overlay pavement is

continued a sufficient length of time for the con-

reinforced.

crete to start to set. All transverse construction

joints should be located in place of other regularly

spaced transverse joints (contraction or expansion

(5) Doweled and tied contraction joints.

types). There are several types of construction

joints available for use, as shown in figure 15-4 and

as described below. The selection of the type of

(a) Dowels are required in transverse con-

construction joint will depend on such factors as the

traction joints for plain concrete pavements for class

concrete placement procedure (formed or slip-

A and B roads and streets, reinforced concrete

formed) and foundation conditions.

(1) Doweled joint. The doweled joint is the

pavements that use slab lengths greater than those

in table 15-1, and in the last joint at ends of long

best joint for providing load transfer and

paving lanes such as large storage and parking

maintaining slab alignment. It is a desirable joint for

areas. These dowels are required to ensure good

the most adverse conditions such as heavy loading,

joint load transfer under heavy, repeated loads and

high traffic intensity, and lower strength

under conditions where conventional contraction

foundations. However, because the alignment and

joints may have inadequate load transfer because of

placement of the dowel bars are critical to

excessive joint opening. Table 15-2 presents the

satisfactory performance, this type of joint is

size and spacing of dowels.

difficult to construct, especially for slipformed

concrete. However, the doweled joint is required

15-15

Previous Page

Previous Page