TM 5-822-5/AFM 88-7, Chap. 1

c. Jointing Normally, joints, other than those

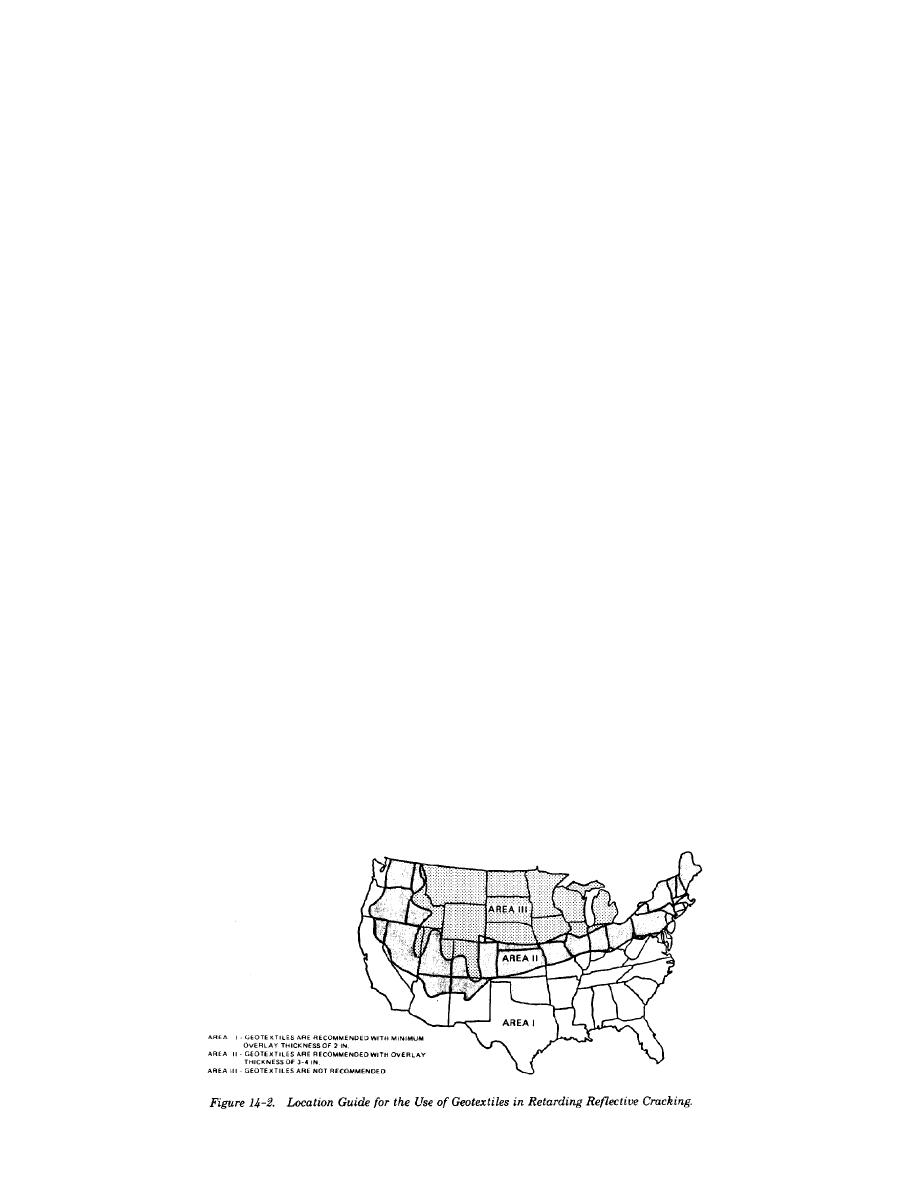

tive cracking in some areas of the United States, as

required for construction of a bituminous concrete

shown in figure 14-2. When geotextiles are used

pavement, will not be required in flexible overlays

under an AC pavement, the existing pavement

of existing rigid pavements. It is good practice to

should be relatively smooth with all cracks larger

attempt to lay out paving lanes in the bituminous

than inch sealed. A leveling course is also rec-

concrete to prevent joints in the overlay from coin-

ommended before application of the fabric to ensure

ciding with joints in the rigid base pavement.

a suitable surface. A tack coat is also required prior

Movements of the existing rigid pavement, both

to placement of the geotextile. The minimum

from contraction and expansion and deflections due

overlay thickness is as shown in figure 14-2. When

to applied loads, cause high concentrated stresses in

using geotextiles under a flexible pavement overlay,

the flexible overlay directly over joints and cracks in

the geotextiles can be used as a membrane strip or

the existing rigid pavements. These stresses may

a full-width application. The existing pavement

result in cracking, often referred to as reflection

should be stable with negligible movement under

cracks, in the overlay. The severity of this type

loads and all joints and cracks larger than inch

cracking will, in part, depend upon the type of rigid

sealed. With the strip method, the geotextile is

pavement. For example, a plain concrete pavement

applied directly on the concrete joints and cracks

normally will have closely spaced joints and may

and then overlaid. With the full-width method, the

result in reflection cracks over the joints, but the

geotextile can be applied directly to the existing

cracks will be fairly tight and less likely to ravel.

pavement or placed on a leveling course. It has also

Nevertheless, reinforced concrete pavements will

been observed that in flexible overlays, the lower

normally have joints spaced farther apart, which

viscosity (or higher penetration grade) asphalts are

will, in turn, experience larger movements. The

less likely to experience reflective cracking.

reflection cracks over these joints are more likely to

Therefore, the lowest viscosity grade asphalt that

ravel and spall. Likewise, either existing plain

will provide sufficient stability during high

concrete or reinforced concrete pavements may

temperatures should be used.

have expansion joints that experience rather large

movements, and consideration may be given to

14-10. Overlays in Frost Regions.

provide an expansion joint in the flexible overlay to

Whenever the subgrade is susceptible to differen-

coincide with the expansion joint in the existing

tial heaving or weakening during the frost-melt

pavement. No practical method has been developed

period, the overlay design should meet the require-

to absolutely prevent reflective cracking in flexible

ments for frost action as given in chapter 17.

overlays; however, experience has shown that the

When it is determined that distress in an existing

degree of cracking is related to the thickness of the

pavement has been caused by differential heaving

overlay, with the thinner overlays exhibiting the

due to frost action, an overlay may not correct the

greater tendency to crack.

condition unless the combined thickness of the

pavement is sufficient to prevent substantial frost

14-9. Use of Geotextiles to Retard Reflective

penetration into the underlying frost-susceptible material.

Cracking.

Geotextiles have been effective in retarding reflec-

14-6

Previous Page

Previous Page