TM 5-822-5/AFM 88-7, Chap. 1

(2) Mismatched

joints.

A

partial

traffic testing. Although some cracking will occur in

reinforcement or slab is required where the joint

the pavement under the design traffic loadings, the

patterns of abutting pavements or adjacent paving

steel rein-forcing will hold the cracks tightly closed.

lanes do Dot match, unless the pavements are

The reinforcing will prevent spalling or faulting at

positively separated by an expansion joint or slip-

the cracks and provide a serviceable pavement

type joint having Dot less than -inch bond-

during the anticipated design life. Essentially, the

breaking medium. The pavement slab directly

design method consists of determining the

opposite the mismatched joint should be reinforced

percentage of steel required, the thickness of the

with a minimum of 0.05 percent of steel in

reinforced concrete pavement, and the minimum

directions normal to each other for a distance of 3

allowable length of the slabs. Figure 13-2 presents

feet back from the juncture and for the full width or

a graphic solution for the design of reinforced

length of the slab in 8 direction normal to the

concrete pavements. Since the thickness of a

mismatched joint. Mismatched joints normally will

reinforced concrete pavement is a function of the

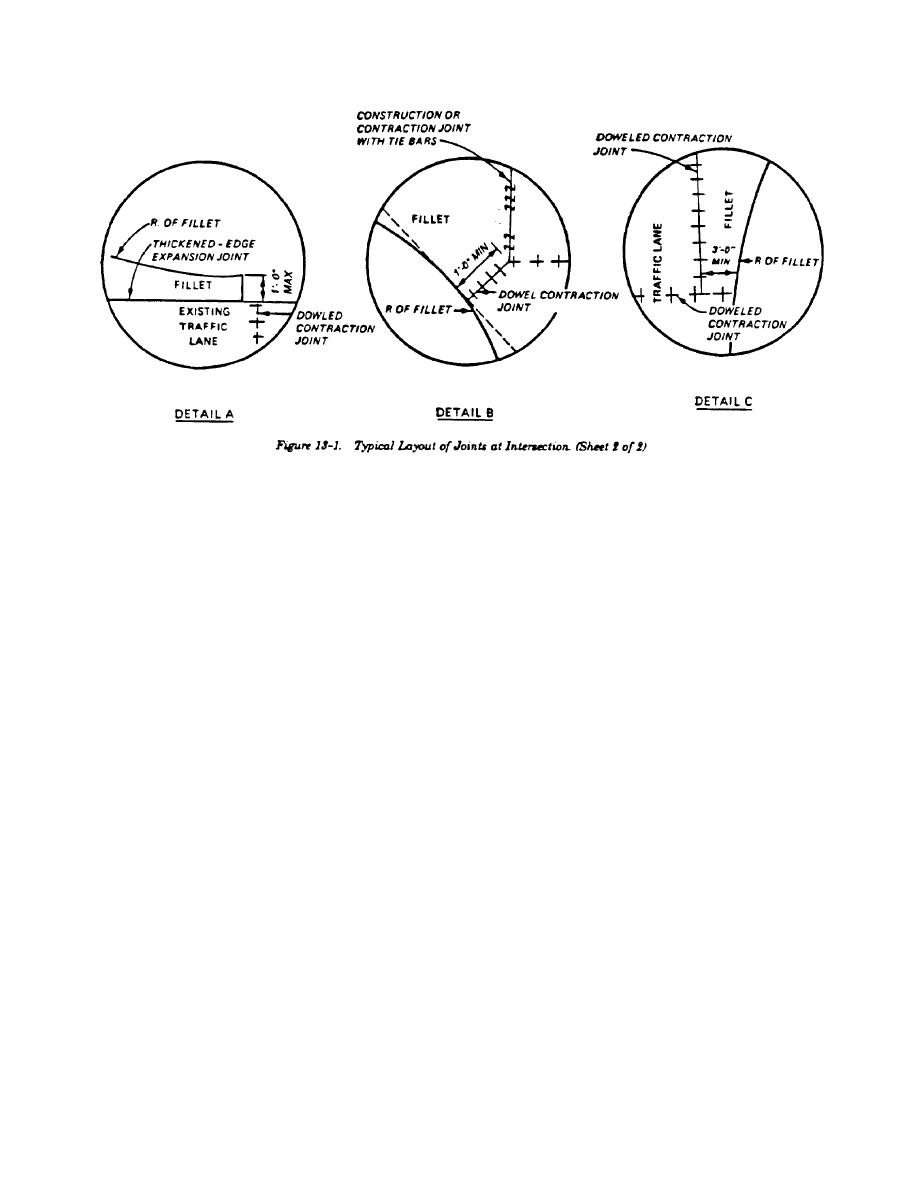

occur at intersections of pavements or between

percentage of steel reinforcing, the designer may

pavement and fillet areas as shown in figure 13-1.

determine either the required percentage of steel for

d. Other uses. Reinforced concrete pavements

a predetermined thickness of pavement or the

may be considered for reasons other than those de-

required thickness of pavement for a predetermined

scribed above provided that a report containing a

percentage of steel. In either case, it is necessary

justification of the need for reinforcement is pre-

first to determine the required thickness of plain

pared and submitted for approval to HQUSACE

concrete pavement by the method outlined

(CEMP-ET) or the appropriate Air Force Major

previously in chapter 12. The plain concrete

Command.

pavement thickness hd (to the nearest 0.1 inch) is

used to enter the nomograph in figure 13-2. A

straight line is then drawn from the value of hd to

13-2. Design Procedure.

the value selected for either the reinforced concrete

a. Thickness design on unbound base or

pavement thickness hr or the percentage of

subbase. The design procedure for reinforced

reinforcing steel S. It should be noted that the S

concrete pavements uses the principle of allowing a

value indicated by figure 13-2 is the percentage to

reduction in the required thickness of plain concrete

be used in the longitudinal direction only. For

pavement due to the presence of the steel

normal designs, the percentage of steel used in the

reinforcing. The design procedure has been

transverse direction will be one- half of that to be

developed empirically from a limited Dumber of

used in the longitudinal direction. In fillets, the

prototype test pavements subjected to accelerated

percent steel will be the same in both directions.

13-3

Previous Page

Previous Page