UFC 3-240-13FN

25 May 2005

8. When the boiler is completely cool, add more water to ensure it is full.

Maintain a pressure of 35 to 69 kilopascals during layup and maintain the

levels of alkalinity and sulfite.

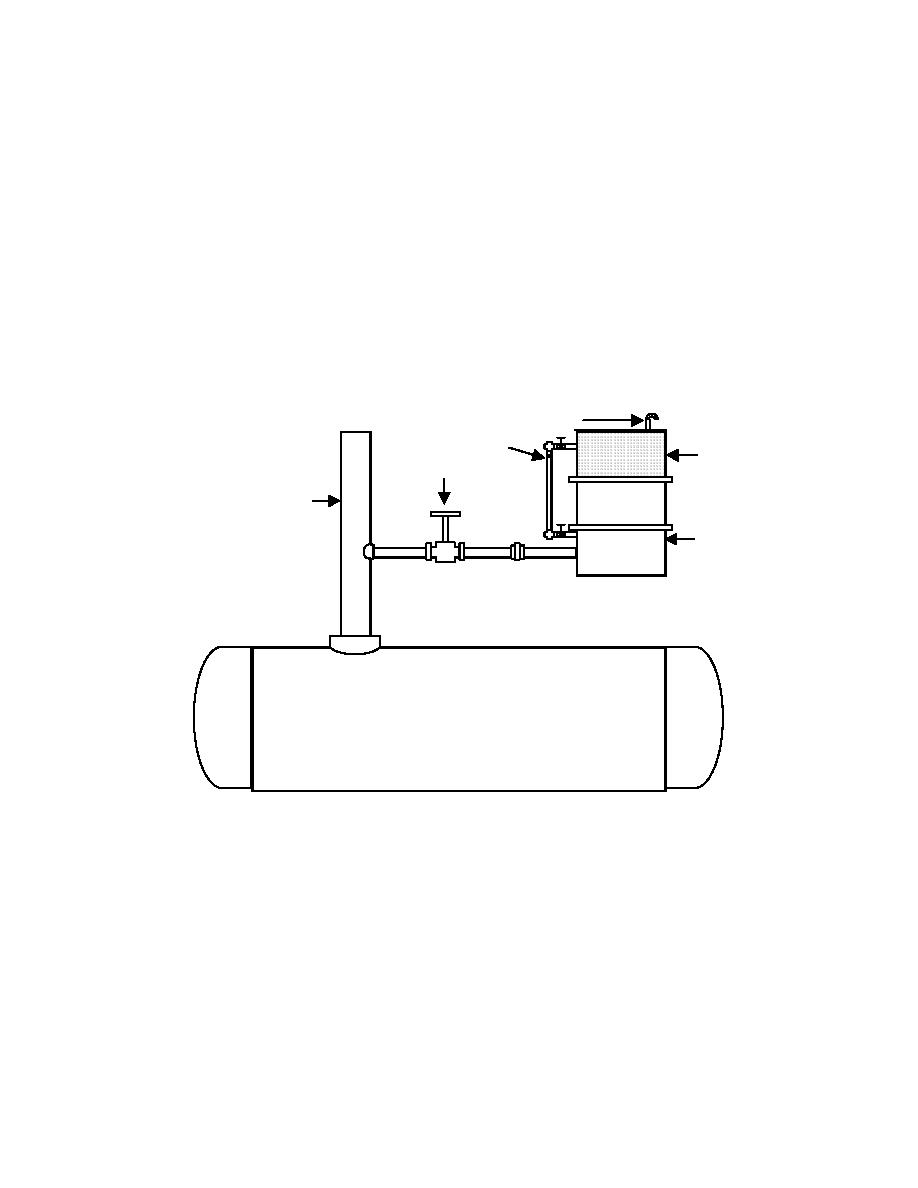

9. Inspect the boiler on a regular basis and replace any water losses. To

facilitate inspections, a small steel tank equipped with a gauge glass can

be installed above the top of the boiler, as shown in Figure 3-15. Fill the

tank with treated water and connect to a steam takeoff tap, vent, or safety

valve connection. A glance at the water level in the small drum will quickly

tell whether or not the boiler is completely filled.

Figure 3-15. Inspection Gauge for Wet Boiler Layup

Gooseneck Vent

Water

Sight Glass

Any Suitable

Level

Valve

Boiler

Small

Connection

Steel

Drum

Boiler Steam Drum

3-5.5

Layup of Condensate Systems. Layup of condensate systems is much

more difficult than layup of boilers. As the system cools, oxygen will be drawn in,

resulting in a situation that leads to corrosion. Purging the system with dry, inert gas can

be effective, but the logistics can be nearly impossible and the hazards include the

potential for suffocating people if the system is located in an unvented area. Application

of a high dosage of a filming amine prior to shut down can be effective, but its use is

restricted for many applications and is prohibited in military operations. Application of a

high dosage of neutralizing amines (see paragraph 3-2.7.3) or of a specialty volatile

oxygen scavenger (see paragraph 3-2.7.5) can be helpful. The application of any amine

or specialty volatile oxygen scavenger can be limited where steam purity or FDA

restrictions exist.

87

Previous Page

Previous Page