UFC 3-240-13FN

25 May 2005

COC = Bmhos / Fmhos

EQUATION

or

(5)

5000 mhos / 250 mhos = 20 COC

b) The percent blowdown is:

%B = 100/COC

EQUATION

or

(6)

100/20 = 5%

c) If the boiler is producing 5 kilograms per second of steam (40,000 pounds

per hour), the blowdown must be:

EQUATION

B = E (COC - 1)

(7)

= 5.0 (20 - 1) = 0.26 kg/s (2105 lb/hr)

d) The feedwater is calculated to be:

EQUATION

F = E + B = 5.0 + 0.26 = 5.26 kg/s (42,105 lb/hr)

(8)

This is equivalent to 5.3 liters per second (5054 gallons per hour at 8.33

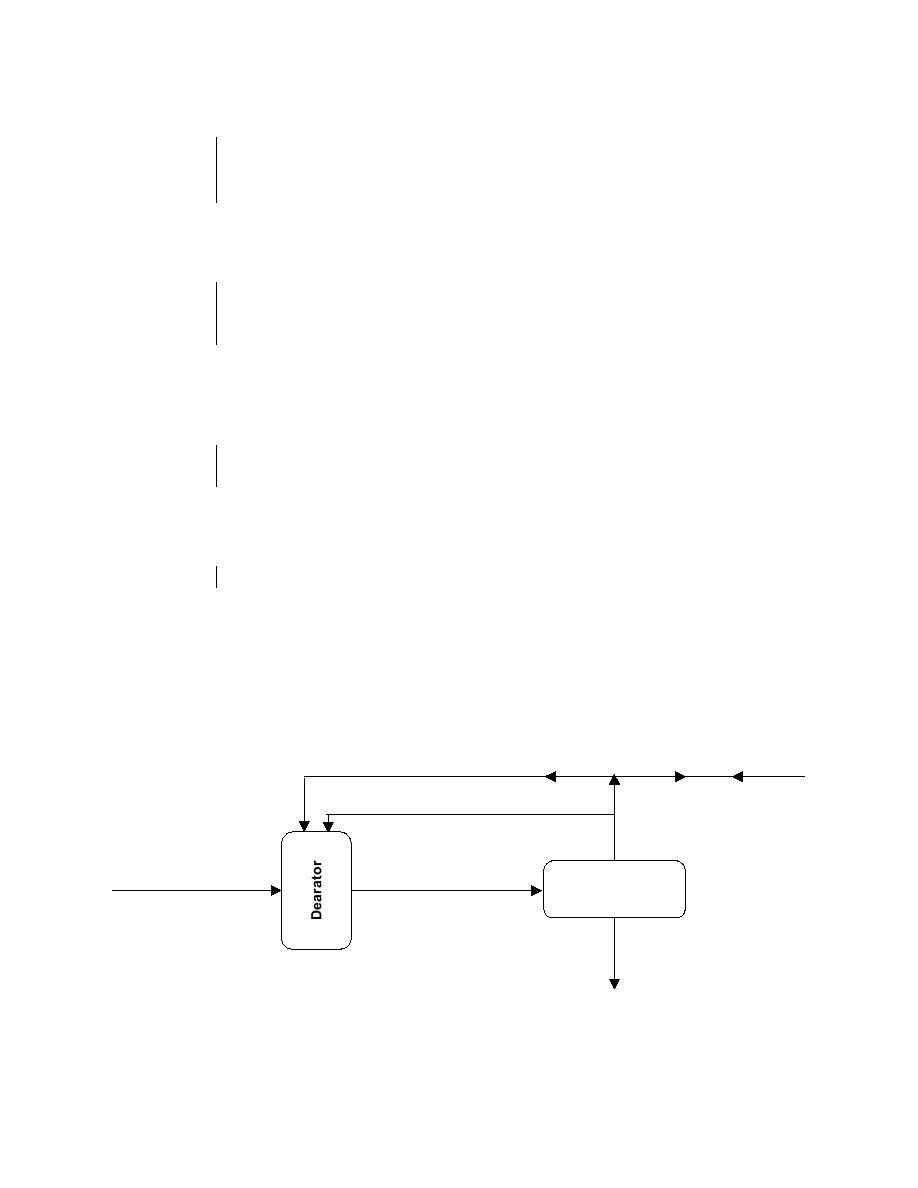

pounds per gallon). This example is illustrated in Figure 3-9.

Figure 3-9. Simplified Boiler System Water Balance

Condensate Return (R)

Steam Lost (L)

3.8 kg/s

1.2 kg/s

(30,316 lb/hr)

(9684 lb/hr)

Pegging Steam

Steam Generated (E)

5 kg/s

Feedwater (F)

(40,000 lb/hr)

5.26 kg/s

Makeup (M)

(42,105 lb/hr)

Steam Boiler

1.5 kg/s

(11,789 lb/hr)

Blowdown (B)

0.26 kg/s

(2105 lb/hr)

3-1.6

Determining Makeup Water and Condensate Return Rates. Makeup is

the water from the external water treatment system added to the boiler system

44

Previous Page

Previous Page