TM 5-818-8lAFJMAN 32-1030

(2) For thickness design using geotextile.

(a) A value of 5.0 for NC would result in a

thickness design that would perform with very

little rutting (less than 2 inches) at traffic vol-

umes greater than 1,000 equivalent 18-kip axle

loadings.

(b) A value of 6.0 for NC would result in a

thickness design that would rut 4 inches or more

under a small amount of traffic (probably less than

100 equivalent 18-kip axle loadings).

e. Geotextile reinforced gravel road design exam-

ple. Design a geotextile reinforced gravel road for

a 24,000-pound-tandem-wheel load on a soil having

a CBR of 1. The road will have to support several

thousand truck passes and very little rutting will

be allowed.

(1) Determine the required aggregate thick-

ness with geotextile reinforcement.

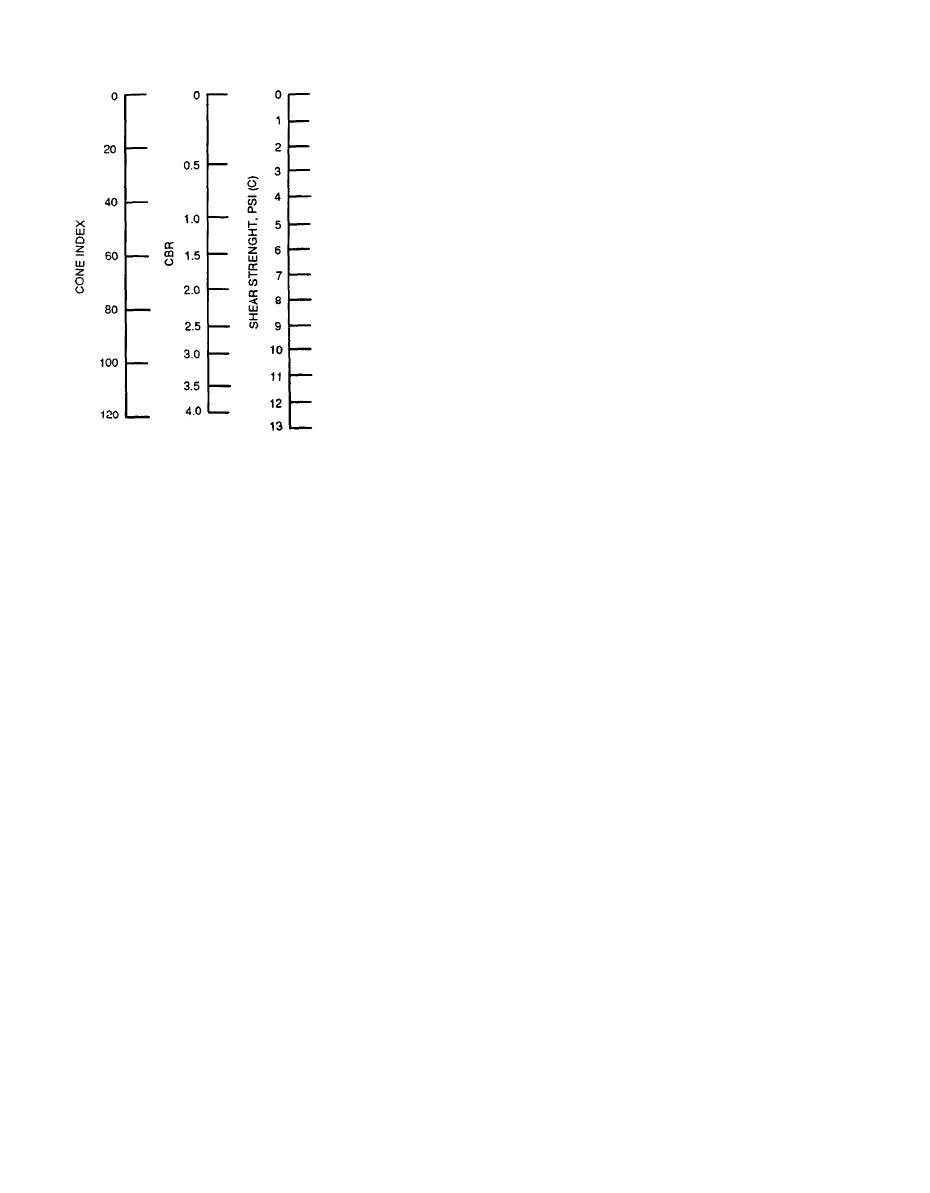

(a) From figure 2-3 a 1 CBR is equal to a C

value of 4.20.

(b) Choose a value of 5 for NC since very

Figure 2-3. Relationship Between Shear Strength, CBR,

little rutting will be allowed.

and Cone Index.

(c) Calculate CN C as: CNC = 4.20(5) = 21.

c. Select Design Loading. Select the desired de-

(d) Enter figure 2-6 with CN C of 21 to

sign loading, normally the maximum axle loads.

obtain a value of 14 inches as the required

d. Determine Required Thickness of Aggregate.

aggregate thickness above the geotextile.

Determine the required thickness of aggregate

(e) Select geotextile requirements based on

survivability requirements in tables 2-2 and 2-3.

above the geotextile using figures 2-4, 2-5, and

(2) Determine the required aggregate thick-

2-6. These figures relate the depth of aggregate

ness when a geotextile is not used.

above the geotextile to the cohesion of the soil (C)

(a) Use a value of 2.8 for NC since a geotex-

and to a bearing capacity factor (NC). The product

tile is not used and only a small amount of rutting

of C and NC is the bearing capacity for a rapidly

will be allowed.

loaded soil without permitting drainage. The sig-

(b) C a l c u l a t e C NC as: CNC = 4.20(2.8) =

nificance of the value used for NC as it relates to

11.8.

the design thickness using figures 2-4, 2-5, and

(c) Enter figure 2-6 with CNC of 11.8 to

2-6 is as follows:

obtain a value of 22 inches as the required

(1) For thickness design without using geotex-

tile.

aggregate thickness above the subgrade without

(a) A value of 2.8 for NC would result in a

the geotextile.

thickness design that would perform with very

(3) Compare cost and benefits of the alterna-

little rutting (less than 2 inches) at traffic volumes

tives. Even with nearby economical gravel sources,

greater than 1,000 equivalent 18-kip axle loadings.

the use of a geotextile usually is the more econom-

ical alternative for constructing low volume roads

(b) A value of 3.3 for NC would result in a

thickness design that would rut 4 inches or more

and airfields over soft cohesive soils. Additionally,

under a small amount of traffic (probably less than

it results in a faster time to completion once the

100 equivalent 18-kip axle loadings).

geotextiles are delivered on site.

2-6

Previous Page

Previous Page