TM 5-818-8/AFJMAN 32-1030

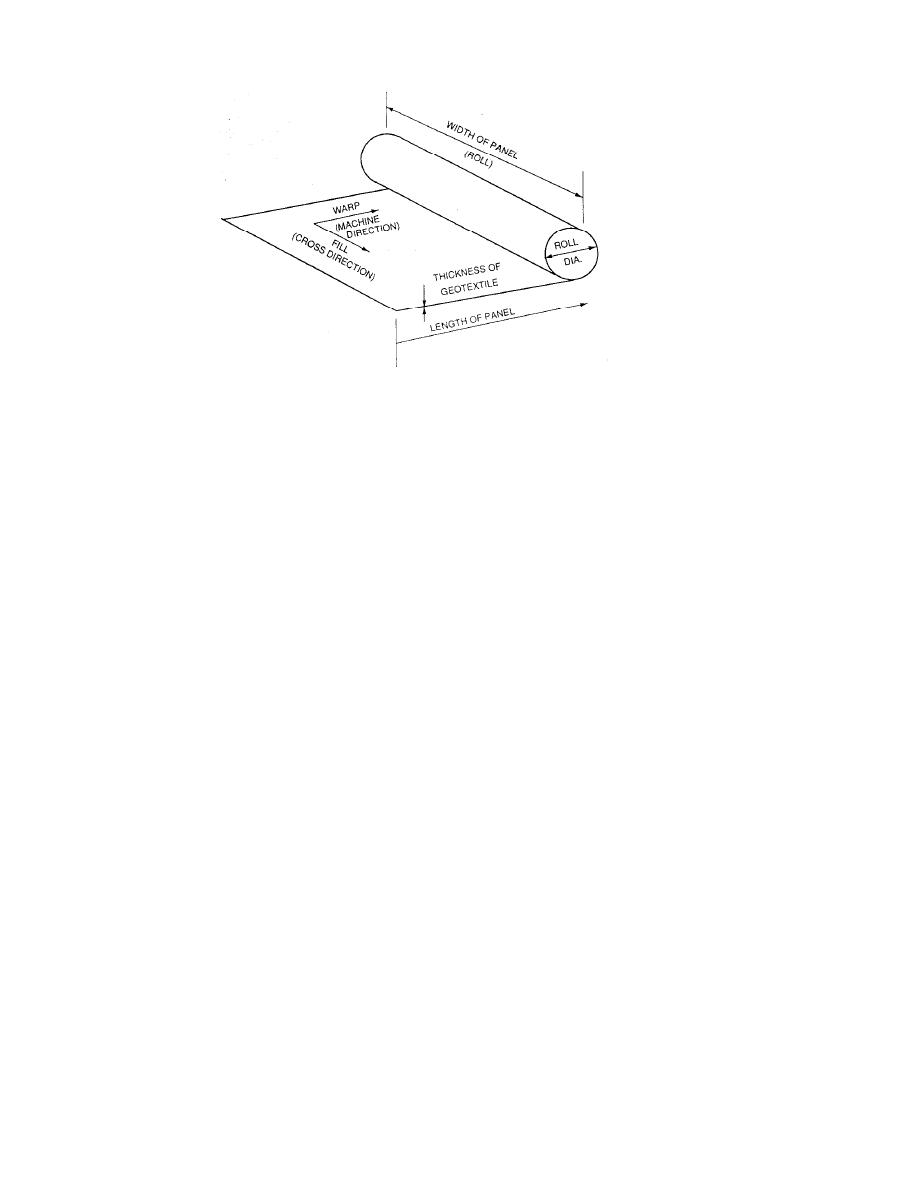

Figure 1-1. Dimensions and Directions for Woven Geotextiles.

rating fibers of the same polymer type but having

material cannot easily be periodically inspected or

different melting points in the mat, or by using

easily replaced if it should become degraded (for

heterofilaments, that is, fibers composed of one

example filtration and/or drainage functions

type of polymer on the inside and covered or

within an earth dam), current practice is to use

sheathed with a polymer having a lower melting

only geologic materials (which are orders of magni-

point. A heat-bonded geotextile is shown in figure

tude more resistant to these weathering effects

l-6.

than polyesters).

1-6. Seam Strength

the fiber mat, coating the fibers and bonding the

a. Joining Panels. Geotextile sections can be

contacts between fibers.

joined by sewing, stapling, heat welding, tying,

(d) Combination bonding. Sometimes a com-

and gluing. Simple overlapping and staking or

bination of bonding techniques is used to facilitate

nailing to the underlying soil may be all that is

manufacturing or obtain desired properties.

necessary where the primary purpose is to hold

(4) Composite geotextiles are materials which

the material in place during installation. However,

combine two or more of the fabrication techniques.

where two sections are joined and must withstand

The most common composite geotextile is a non-

tensile stress or where the security of the connec-

woven mat that has been bonded by needle punch-

tion is of prime importance, sewing is the most

ing to one or both sides of a woven scrim.

reliable joining method.

1-5. Geotextile Durability

b. Sewn Seams. More secure seams can be pro-

duced in a manufacturing plant than in the field.

Exposure to sunlight degrades the physical proper-

The types of sewn seams which can be produced in

ties of polymers. The rate of degradation is re-

the field by portable sewing machines are pre-

duced by the addition of carbon black but not

sented in figure 1-7. The seam type designations

eliminated. Hot asphalt can approach the melting

are from Federal Standard 751. The SSa seam is

point of some polymers. Polymer materials become

referred to as a "prayer" seam, the SSn seam as a

brittle in very cold temperatures. Chemicals in the

"J" seam, and the SSd as a "butterfly" seam. The

groundwater can react with polymers. All poly-

double-sewn seam, SSa-2, is the preferred method

mers gain water with time if water is present.

for salvageable geotextiles. However, where the

High pH water can be harsh on polyesters while

edges of the geotextile are subject to unraveling,

low pH water can be harsh on polyamides. Where

SSd or SSn seams are preferred.

a chemically unusual environment exists, labora-

c. Stitch Type. The portable sewing machines

tory test data on effects of exposure of the geotex-

used for field sewing of geotextiles were designed

tile to this environment should be sought. Experi-

as bag closing machines. These machines can

ence with geotextiles in place spans only about 30

produce either the single-thread or two-thread

years. All of these factors should be considered in

chain stitches as shown in figure l-8. Both of

selecting or specifying acceptable geotextile mate-

these stitches are subject to unraveling, but the

rials. Where long duration integrity of the mate-

single-thread stitch is much more susceptible and

rial is critical to life safety and where the in-place

1-2

Previous Page

Previous Page