due to sedimentation, and (c) maintenance of circulation with hole closed down

If the grout take is large, a single -line system may be preferred because of

i t s simplicity.

( 2 ) Operation. The batch system is more satisfactory than continuous

mix. The necessary water for each batch should be run into the mixer and

the cement dumped in as needed. After mixing thoroughly, the batch of grout

should be dumped into the agitator for pumping, and the next batch started in

the mixer to prevent delays between batches. On slow holes or where only

small quantities of grout are injected at one time, one man may be able to

operate both mixer and pump. On some portable plants the pump and mixer

are mounted with control valves arranged so that one man can operate both

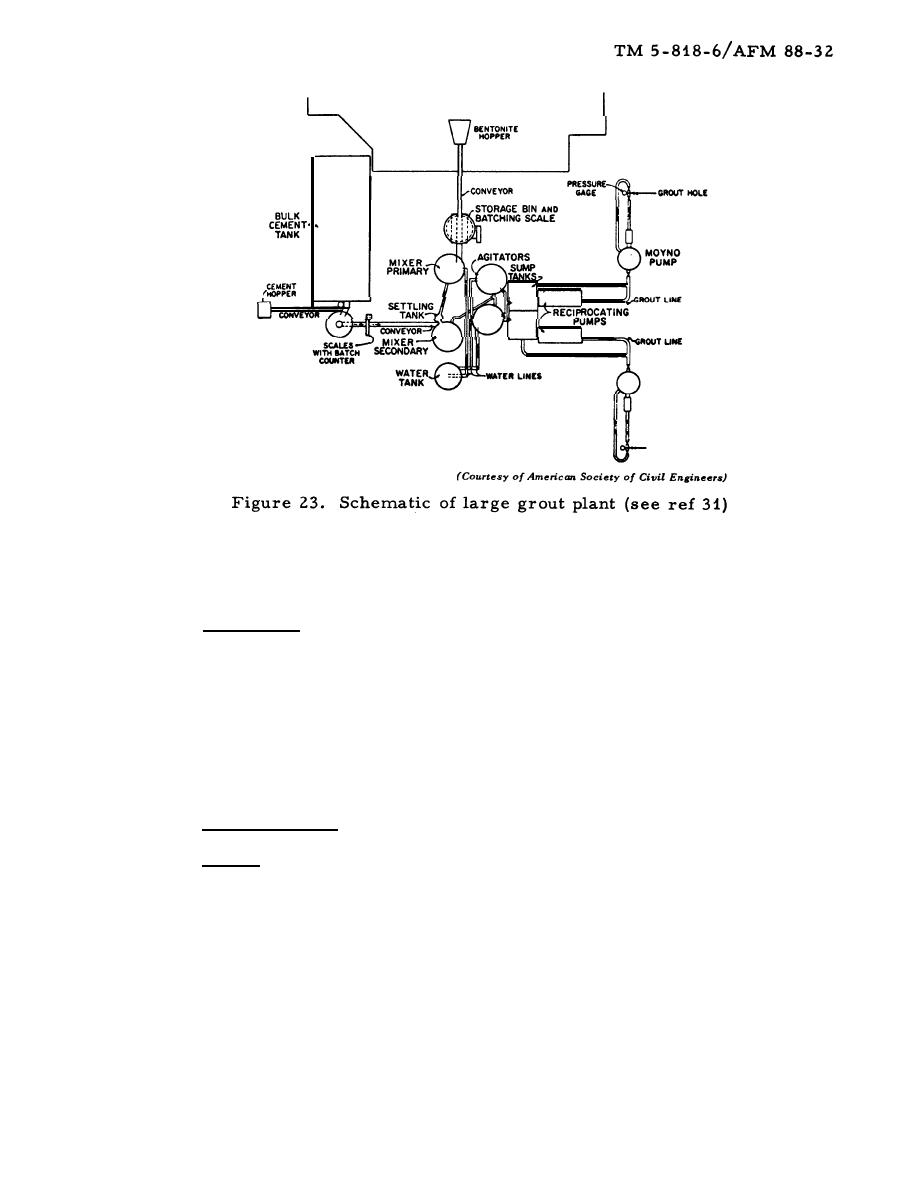

pieces of equipment. F o r large operations, batching systems may be set up

for automatic control with one operator.

b . Clay Grouting.

( 1 ) Plant. Where processed clays such as commercial bentonites are

used as the grout material, the grout plant and operation are similar to those

used in cement grouting. When natural soils are used, the plant may have to

be modified to allow for processing the raw material. Where this is neces-

sary, in addition to the basic plant as shown for cement grouting, a drying

63

Previous Page

Previous Page