against a column of water or mercury. F o r accurate low pressures, low-

pressure gages should be used. The dial of any gage in use should be care-

fully inspected. Many gages require a pressure equal to that measured by

one increment on the dial to initiate movement of the indicator needle. In

such a case, the first mark on the dial of a gage showing increments of 5 psi

may actually indicate a pressure of 10 psi. This could be critical for near-

surface grouting where low pressures have to be carefully controlled. For

very low pressures and sensitive conditions, a standpipe is sometimes used

to prevent excessive pressures from being applied. The standpipe extends

only high enough above the top of the hole to obtain the desired pressure by

the weight of the grout column in the pipe. The grout line is inserted into but

not connected to the standpipe. Thus, grout will overflow if it is supplied

faster than the hole can accommodate it. An adjustment in the height of the

standpipe is required for each mix used if the same pressure is maintained.

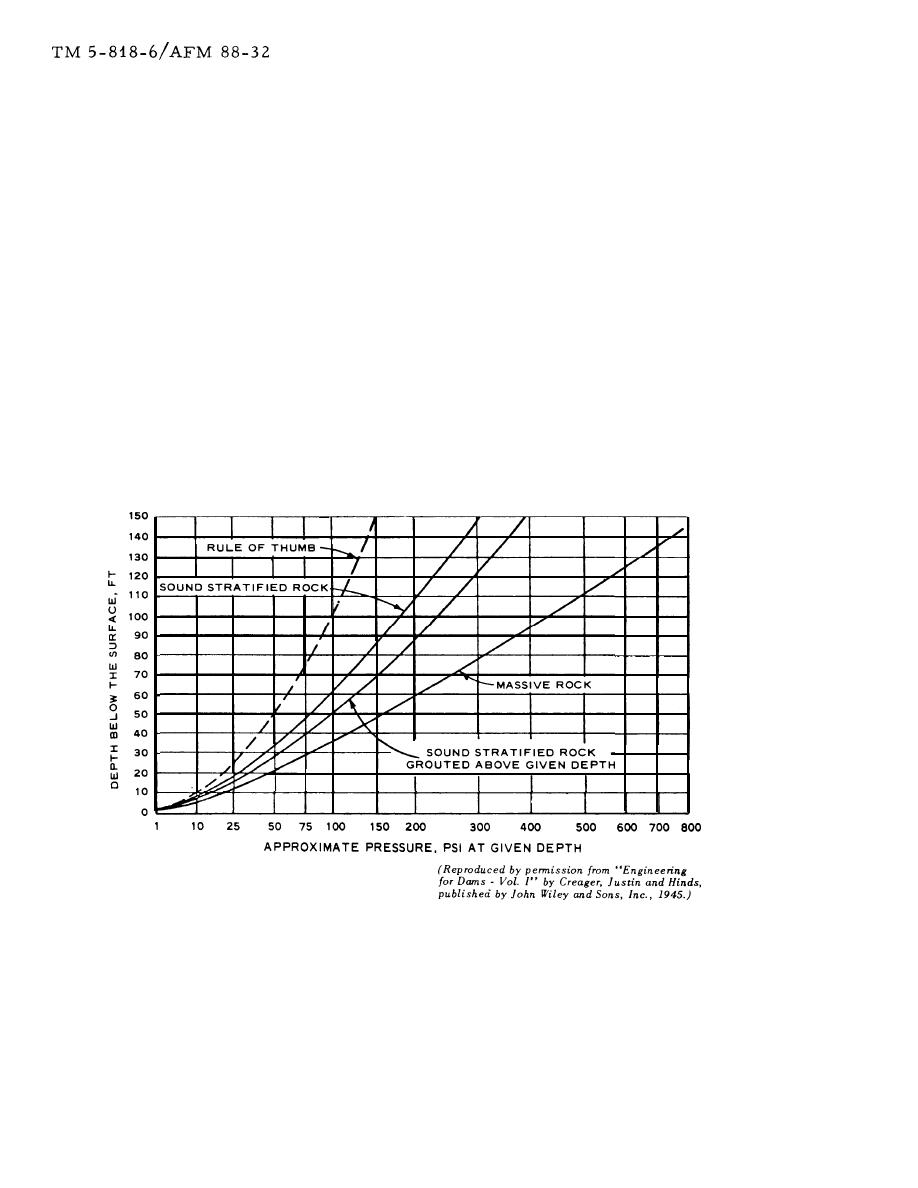

(2) There is no way to precisely determine the maximum safe grouting

pressure for a particular zone of grouting. A rule of thumb states that 1 lb

of pressure per square inch can be used for each 1 ft of rock and each 2 ft

of soil vertically above the point of grout injection. ( S i m i l a r coverage is

needed in directions other than vertical. ) The rule of thumb can be modified

with caution as indicated in figure 3. The weight of the column of grout in

Figure

3.

Rough guide for grouting pressures

24

Previous Page

Previous Page