TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

(Modified from "Foundation Engineering, "G. A. Leonards. ed.. 1962, McGraw-Hill Book

Company. Used with permission of McGraw-Hill Book Company.)

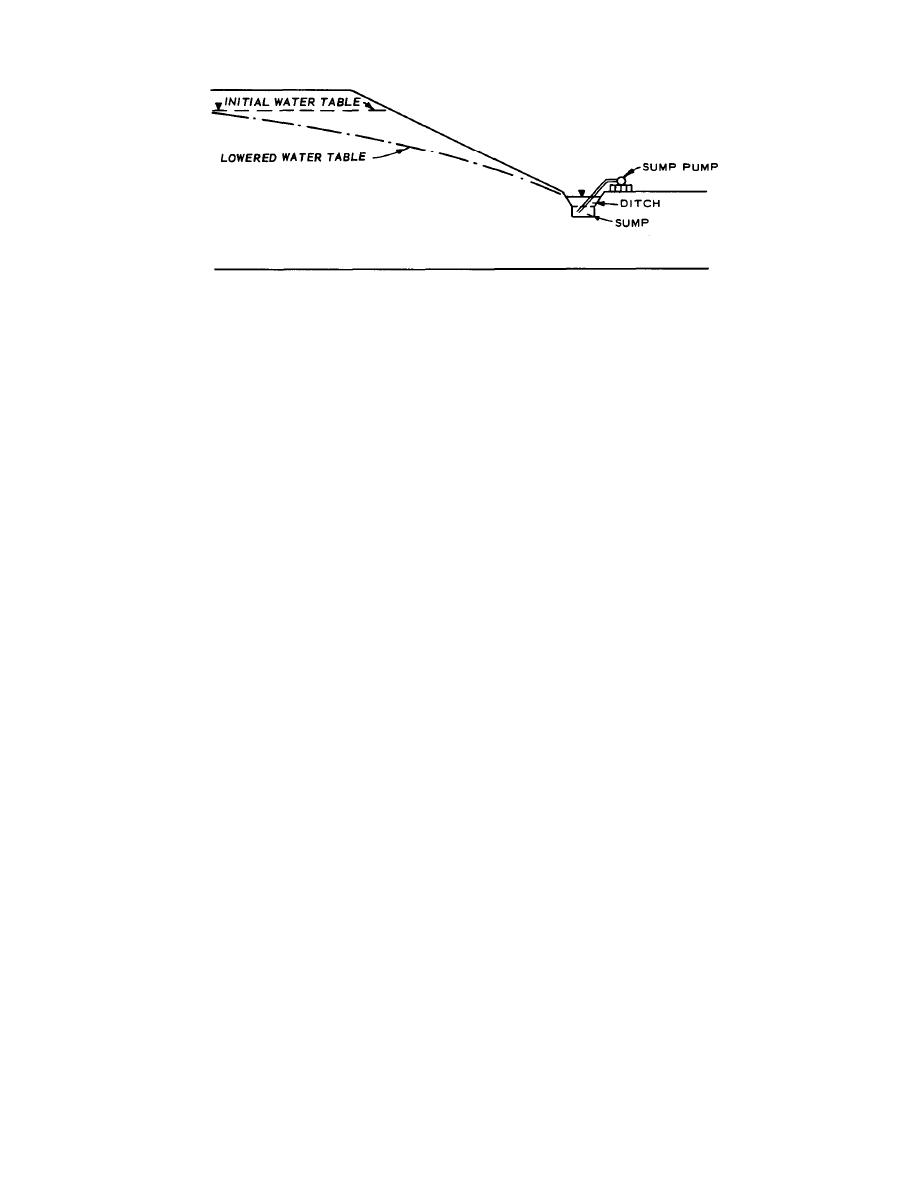

Figure 2-1. Dewatering open excavation by ditch and sump.

be considered where the groundwater head must be

cable to a wide range of excavations and groundwater

lowered more than a few feet, as seepage into the ex-

conditions.

cavation may impair the stability of excavation slopes

a. Conventional wellpoint systems. A conventional

or have a detrimental effect on the integrity of the

wellpoint system consists of one or more stages of

foundation soils. Filter blankets or drains may be in-

wellpoints having 1 or 2-inch-diameter riser pipes,

cluded in a sump and ditch system to overcome minor

installed in a line or ring at spacings between about 3

raveling and facilitate collection of seepage. Dis-

and 10 feet, with the risers connected to a common

advantages of a sump dewatering system are slowness

header pumped with one or more wellpoint pumps.

in drainage of the slopes; potentially wet conditions

Wellpoints are small well screens composed of either

during excavation and backfilling, which may impede

brass or stainless steel mesh, slotted brass or plastic

construction and adversely affect the subgrade soil;

pipe, or trapezoidal-shaped wire wrapped on rods to

space required in the bottom of the excavation for

form a screen. They generally range in size from 2 to 4

drains, ditches, sumps, and pumps; and the frequent

inches in diameter and 2 to 5 feet in length and are

lack of workmen who are skilled in the proper con-

constructed with either closed ends or self-jetting tips

struction or operation of sumps.

as shown in figure 2-2. They may or may not be sur-

rounded with a filter depending upon the type of soil

b. Cofferdams. A common method of excavating

drained. Wellpoint screens and riser pipes may be as

below the groundwater table in confined areas is to

drive wood or steel sheet piling below subgrade ele-

large as 6 inches and as long as 25 feet in certain situa-

vation, install bracing, excavate the earth, and pump

tions. A wellpoint pump uses a combined vacuum and

a centrifugal pump connected to the header to produce

out any seepage that enters the cofferdammed area.

(1) Dewatering a sheeted excavation with sumps

a vacuum in the system and to pump out the water

and ditches is subject to the same limitations and seri-

that drains to the wellpoints. One or more sup-

plementary vacuum pumps may be added to the main

ous disadvantages as for open excavations. However,

the danger of hydraulic heave in the bottom of an ex-

pumps where additional air handling capacity is re-

cavation in sand may be reduced where the sheeting

quired or desirable. Generally, a stage of wellpoints

can be driven into an underlying impermeable stra-

(wellpoints connected to a header at a common eleva-

tum, thereby reducing the seepage into the bottom of

tion) is capable of lowering the groundwater table

the excavation.

about 15 feet; lowering the groundwater more than 15

(2) Excavations below the water table can some-

feet generally requires a multistage installation of

times be successfully made using sheeting and sump

wellpoints as shown in figures 2-3 and 2-4. A well-

pumping. However, the sheeting and bracing must be

point system is usually the most practical method for

designed for hydrostatic pressures and reduced toe

dewatering where the site is accessible and where the

support caused by upward seepage forces. Covering

excavation and water-bearing strata to be drained are

the bottom of the excavation with an inverted sand

not too deep. For large or deep excavations where the

and gravel filter blanket will facilitate construction

depth of excavation is more than 30 or 40 feet, or

and pumping out seepage water.

where artesian pressure in a deep aquifer must be re-

duced, it may be more practical to use eductor-type

2-4. Wellpoint systems. Wellpoint systems are

wellpoints or deep wells (discussed subsequently) with

a commonly used dewatering method as they are appli-

turbine or submersible pumps, using wellpoints as a

2-2

Previous Page

Previous Page