UFC 3-220-01N

15 AUGUST 2005

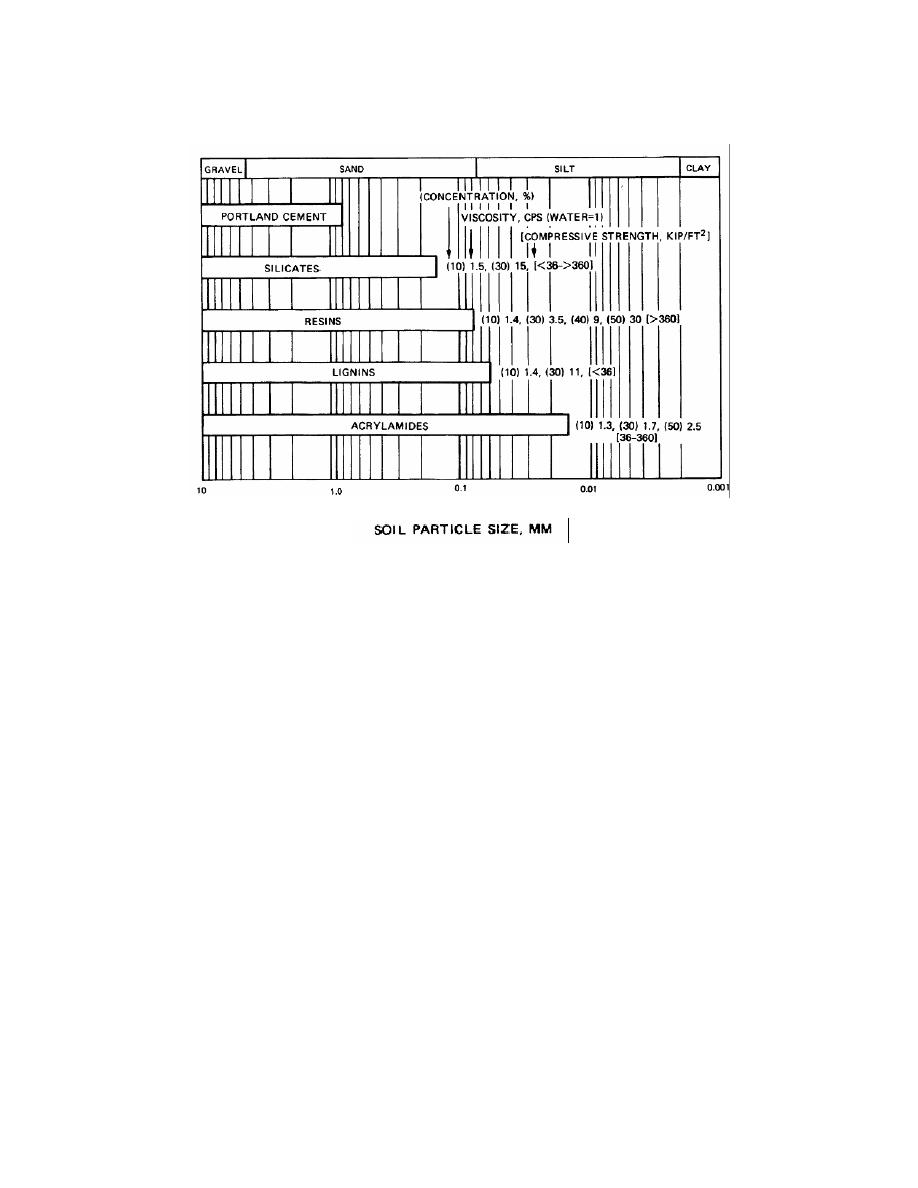

Figure 8-7.6 Soil Particle Sizes Suitable for Different Grout Types and Several

Concentrations and Viscosities Shown

8-7.6

Reinforcement. The supporting capacity of soft, compressible ground

may be increased and settlement reduced through use of compression reinforcement in

the direction parallel to the applied stress or tensile reinforcement in planes normal to

the direction of applied stress. Commonly used compression reinforcement elements

include mix-in-place piles and walls. Strips and membranes are used for tensile

reinforcement, with the latter sometimes used to form a moisture barrier as well.

8-7.6.1

Mix-in-Place Piles and Walls. Several procedures are available, most of

them patented or proprietary, which enable construction of soil-cement or soil-lime in

situ. A special hollow rod with rotating vanes is augered into the ground to the desired

depth. Simultaneously, the stabilizing admixture is introduced. The result is a pile of up

to 0.6 meters (2 feet) in diameter. Cement, in amounts of 5 to 10 percent of the dry soil

weight, is best for use in sandy soils. Compressive strengths in excess of 9.6 mPa (200

kips) per sq ft can be obtained in these materials. Lime is effective in both expansive

plastic clays and in saturated soft clay. Compressive strengths of about 0.96 1.92

kPa (20 to 40 kips) per square foot are to be expected in these materials. If overlapping

piles are formed, a mix-in-place wall results.

8-7.6.2

Vibroreplacement Stone Columns. A vibroflot is used to make a

cylindrical, vertical hole under its own weight by jetting to the desired depth. Then, up to

( to 1 in) diameter is dumped in, and the vibroflot is used to compact the gravel

vertically and radially into the surrounding soft soil. This process of backfilling and

compaction by vibration is continued until the densified stone column reaches the

surface.

8-101

Previous Page

Previous Page