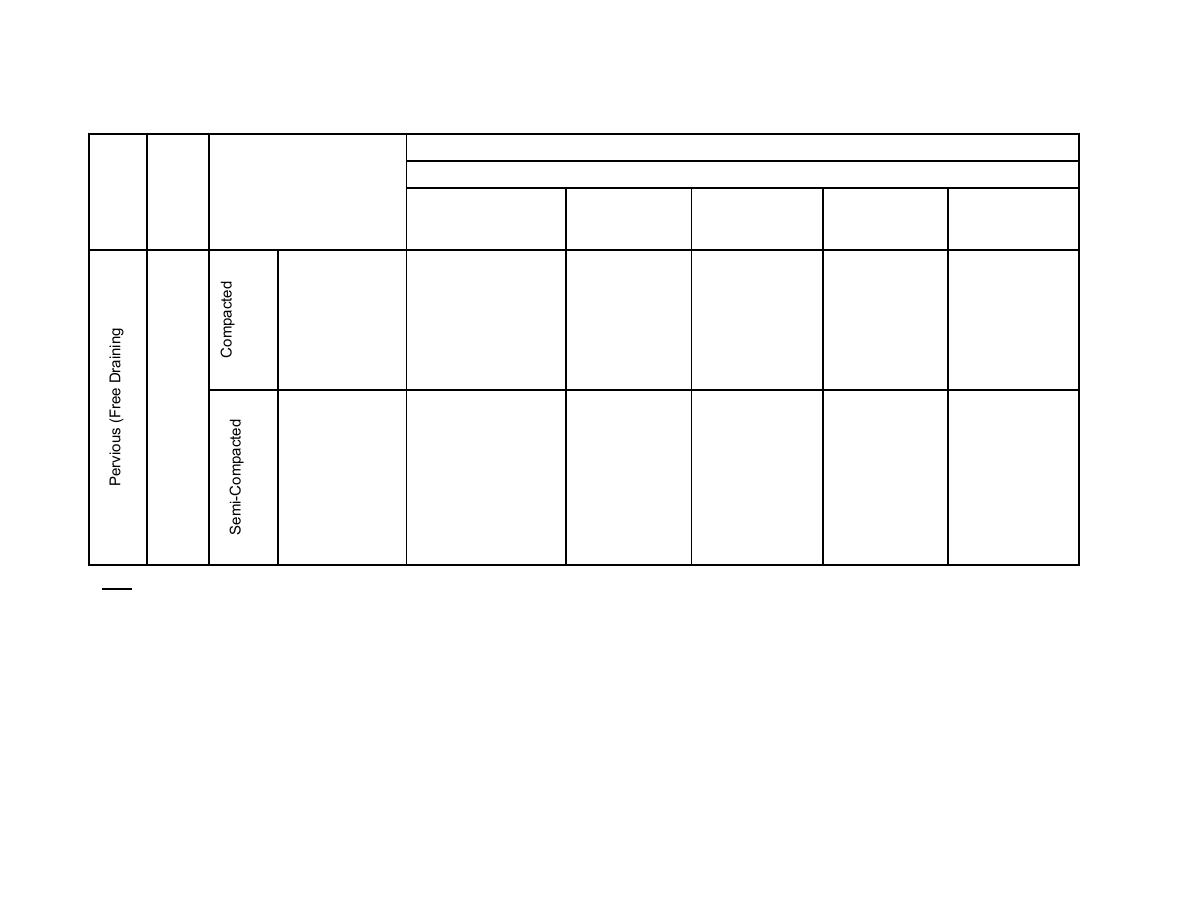

Table 8-5.1 Summary of Compaction Criteriaa

Fill and Backfill

Typical Equipment and Procedures for Compaction

Soil

Soil

Degree of Compaction

Equipment

No. of Passes

Comp. Lift

Placement

Field Control

Group

Types

or Coverages

Thickness mm

Water Content

(in)

GW

90 95% of CE

Vibratory Rollers

Indefinite

Indefinite

Saturate by

Control tests at

55 maximum

intervals to

Rubber Tired Rollerb

GP

2-5 Coverages

300 (12)

density

determine

degree of

SW

Crawler Type

2-5 Coverages

200 (8)

75 85% of

Tractorc

compaction or

relative density

SP

Indefinite

150 (6)

relative density

Power Hand

Tamperd

Rubber Tired Rollerb

85 to 90% of CE

2-5 Coverages

360 (14)

Saturate by

Control tests at

55 maximum

intervals to

Crawler Type

1-2 Coverages

250 (10)

density

determine

Tractorc

degree of

Indefinite

200 (8)

65 to 75% of

compaction or

Power Hand

relative density

Indefinite

200250 (8-10)

Tamperd

relative density,

if needed

Controlled routing of

construction

equipment

Note: The above requirements will be adequate in most construction venues. In special cases where tolerable settlements are unusually small, it may be necessary to

employ additional compaction equivalents to 95-100% of compaction effort. A coverage consists of one application of the wheel of a rubber tired roller or the treads of a

crawler type tractor over each point in the area being compacted. For a sheepsfoot roller , one pass consists of one movement of a sheepsfoot roller drum over the area

being compacted.

a)

From TM 5-818-1

b)

Rubber tired rollers having a wheel load between 80 and 111 kN (18,000 and 25,000 lb) with a tire pressure between 552-689 kPa (80-100 psi).

c)

Crawler type tractors weighing not < 89 kN (20,000 lbs) / exerting a foot pressure not < 4.5 kPa (6.5psi).

d)

Power hand tampers weighing more than 0.44 kN (100 lbs) / pneumatic or gasoline powered.

e) Sheepsfoot roller with a foot pressure between 1724-3448 kPa (250-500 psi)/ tamping feet 180-250 mm (7-10 in) long/ face area between 4500-10300 mm2

(7-16 sq. in. )

Previous Page

Previous Page