MIL-HDBK-1110

in Table 13. Additional problems that may occur with airless

spraying may be associated with excessive pressure, undersized

equipment, and too long or too small paint hoses. Undersized

spray equipment, including hoses, may result in lower production

rates, a pebbly-appearing film caused by poor atomization (nozzle

tip too large), and thin films. Air supply hoses that are too

long or too small may cause instability of the pump, poor

atomization of the paint, or a pulsating spray pattern.

Table 13

Common Airless-Spray Problems and Their Causes and Remedies

Remedy

Description

Cause

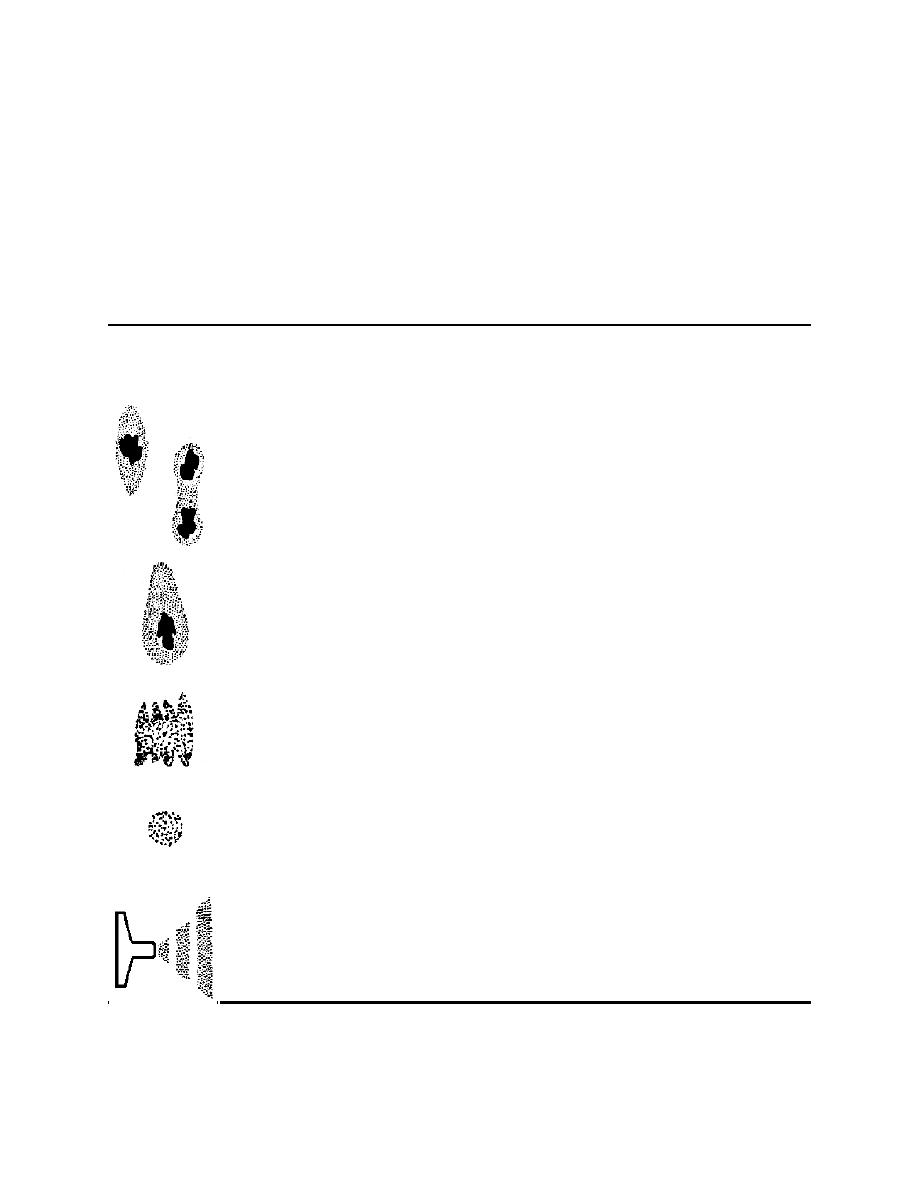

Thick center,

Inadequate fluid

Increase fluid

pressure,

thin ends,

delivery or

decrease paint

pinholes

improper

viscosity, choose larger

atomization

tip orifice, or reduce

and

number of guns using one

pump

hour-glass

shape

Teardrop

Clogged or worn

Clean nozzle tip,

replace

shape coating

nozzle tip if necessary

thicker

Rippling,

Pulsating fluid

Increase supply to air

uneven pattern

delivery or

motor, reduc number of

e

suction leak

guns using one pump,

choose smaller tip

orifice, clean tip

screen and filter, or

look for hose leak

Round pattern

Worn nozzle tip

Replace worn tip,

or fluid too

decrease fluid viscosity

viscous for tip

increase pressure, or

size

choose correct tip

orifice

Fluid spitting

Air entering

Check for hose leak,

system, dirty

clean gun, or adjust

gun, or wrong

cartridge and replace

cartridge

if necessary

adjustment

116

Previous Page

Previous Page