MIL-HDBK-1110

6.6

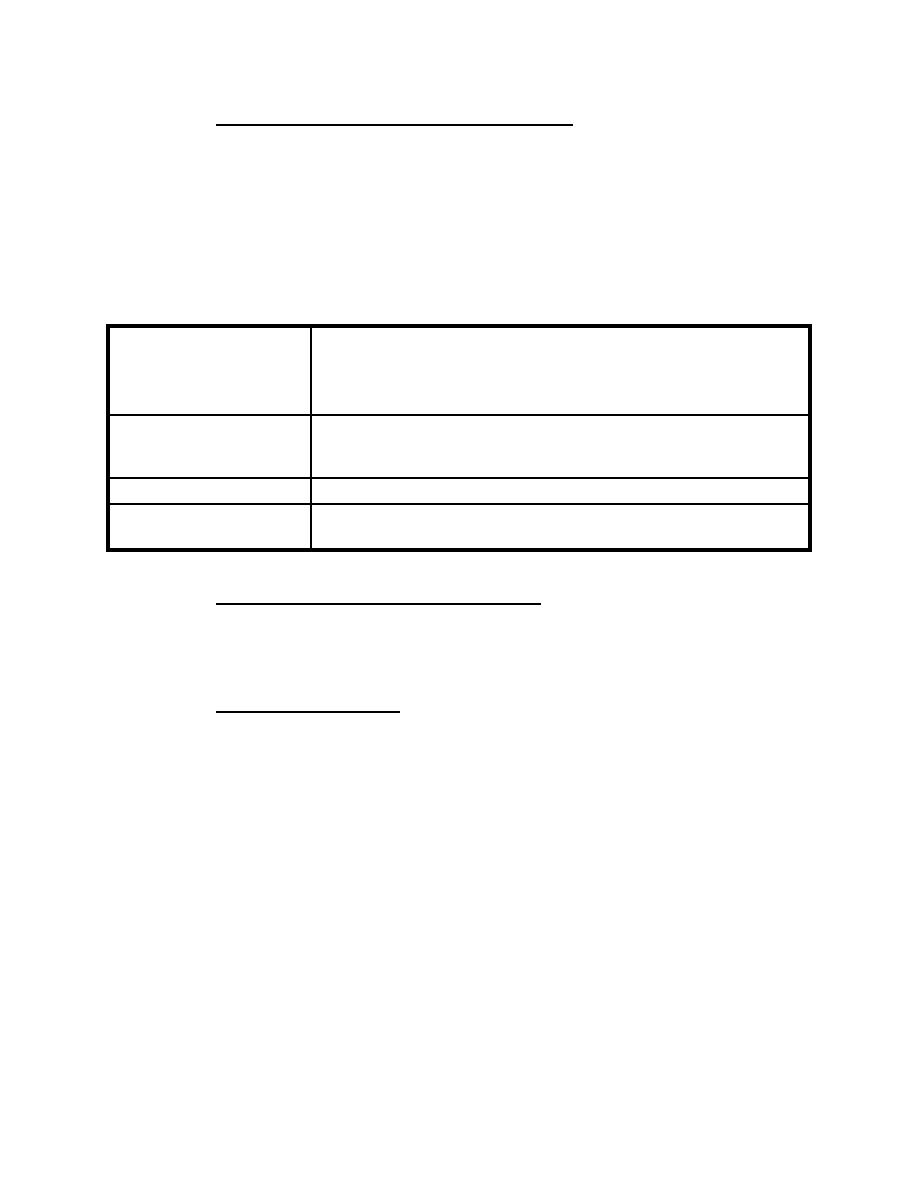

Recommendations for Paint Removal. It is often

necessary to remove old coatings that are peeling, checking,

cracking, or the like. General recommendations for removal of

paint from a variety of substrates are made in Table 8. More

specific information is provided in par. 6.7.

Table 8

Procedures for Coating Removal

(IMPORTANT NOTE - Presence of Leaded Paint Will Require

Environmental and Worker Safety Controls)

Substrate

Methods

Wood

Chemical removers; heat guns or hot plates

along with scraping; power sanding (must be

done with caution to avoid damaging wood).

Masonry

Careful water blasting to avoid substrate

damage; brush-off blasting and power tools,

used with caution.

Steel

Abrasive blasting; water blasting.

Miscellaneous

Chemicals; brush-off blast; water blast

metals

6.7

Methods of Surface Preparation. Information on surface

preparation methods and procedures are presented to help select

appropriate general procedures and to inspect surface preparation

jobs. It is not intended to be a complete source of information

for those doing the work.

6.7.1

Abrasive Blasting. Abrasive blast cleaning is most

often associated with cleaning painted and unpainted steel. It

may also be used with care to prepare concrete and masonry

surfaces and to clean and roughen existing coatings for painting.

Abrasive blasting is an impact cleaning method. High-velocity

abrasive particles driven by air, water, or centrifugal force

impact the surface to remove rust, mill scale, and old paint from

the surfaces. Abrasive cleaning does not remove oil or grease.

If the surface to be abrasive blasted is painted with leaded

paint, additional controls must be employed to minimize hazards

to workers and the surrounding environment. Leaded paint issues

are discussed in more detail in Section 3.

There are four degrees of cleanliness of blast cleaning

designated by the SSPC and the NACE for steel substrates. These

designations are white metal, near-white metal, commercial, and

brush-off. They are described in detail in par. 6.5.1.1. The

81

Previous Page

Previous Page