TM5-805-6

move independently of each other. Stationary

vibration from operating components connected to

the pipe or duct. In fire resistant structures, the

joints can be configured as shown in figures 4 and

gap must be filled with fireproofing material and a

5, except that a bond-breaker is not needed be-

sealant may be required to protect the fireproofing

cause there will be no deformation of the sealant

from traffic or water.

(or caulking). In a stationary joint, the backing

(1) Bare Pipe Sleeve. A bare pipe may pene-

may be rigid material.

trate a wall through a sleeve with sealant in the

b. Moving joints. Joints that move are generally

exterior wall and an escutcheon on the interior as

configured as shown in figures 4 or 5, and in every

shown in figure 10.

case the bottom of a moving joint should be

(2) Above Grade Insulated Pipe. Pipe insula-

protected by a bond-breaker or by a backing

tion should be protected by a metal jacket which

material which can move with the- sealant.

may be sealed to the sleeve as shown in figure 11.

c. Expansion and control joints. Expansion and

(3) Exterior Wall Penetration. Protection from

control joints should be treated as moving joints,

exterior moisture may be required above or below

including those control joints that do not penetrate

grade. The penetration may be isolated from the

the material but provide a weak place where a

waterproofing membrane by a clamping flange

crack can develop in the material beneath the

which also serves to protect the sealant as shown

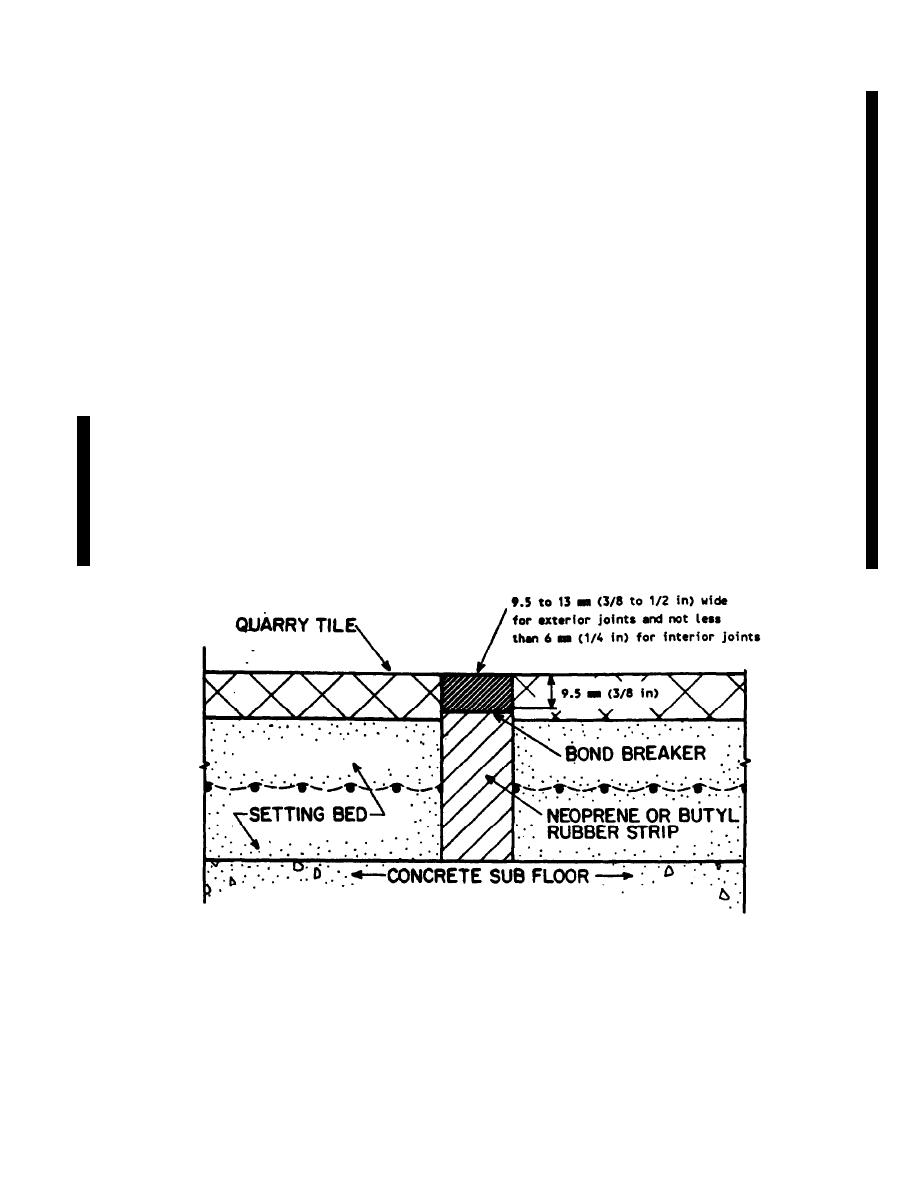

joint. A control or expansion joint in tile is shown

in figure 9.

in figure 12.

(4) Floor Penetration. Sealant around a pipe

d. Pipe and round duct penetrations. A pipe or

penetrating through a floor should be sloped to

round duct must be protected with a sleeve when

avoid trapping water or dirt at the pipe to sealant

penetrating a floor, wall, ceiling or roof. The gap

interface as shown in figure 13.

between pipe and sleeve should be a minimum of 6

e. Typical joints. Table 2 lists typical joints used

mm ( inch) and the gap between duct and sleeve

in construction and provides sealant selection cri-

should be 25 mm (1 inch) or more. Sealants for

teria depending on the anticipated requirements

these g a p s may be selected from table 2. A

for movement, cure time, paint acceptance, and

resilient sealant may be required to absorb move-

resistance to traffic or standing water.

I ment due to thermal expansion or to dampen

Figure 9. Control or Expansion Joint in Tile.

13

Previous Page

Previous Page