TM 5-852-9/AFR 88-19, Vol. IX

because field fabrication and assembly can easily damage the cable or its terminations. The cable is inserted

into a pipe run at a tee or wye fitting with a compression gland connector. Electrical connections can be made

external to the pipe in a dry junction box. Temperature is monitored with either an immersion thermostat or

a thermostat bulb installed under the insulation against the pipe. This method is appropriate for water lines

but should be avoided in sewage lines because of its tendency to cause clogs and blockages.

Third method: Also commonly used is installation of heat cables in small diameter conduits

attached directly to, or in close proximity to, the carrier pipe and under the insulation. This method has been

used successfully with both water and sewer lines. The heat cable lies loose in the conduit, allowing easy

installation and removal. Steam, hot water, or a heated glycol solution may be substituted in lieu of electric

heat cables.

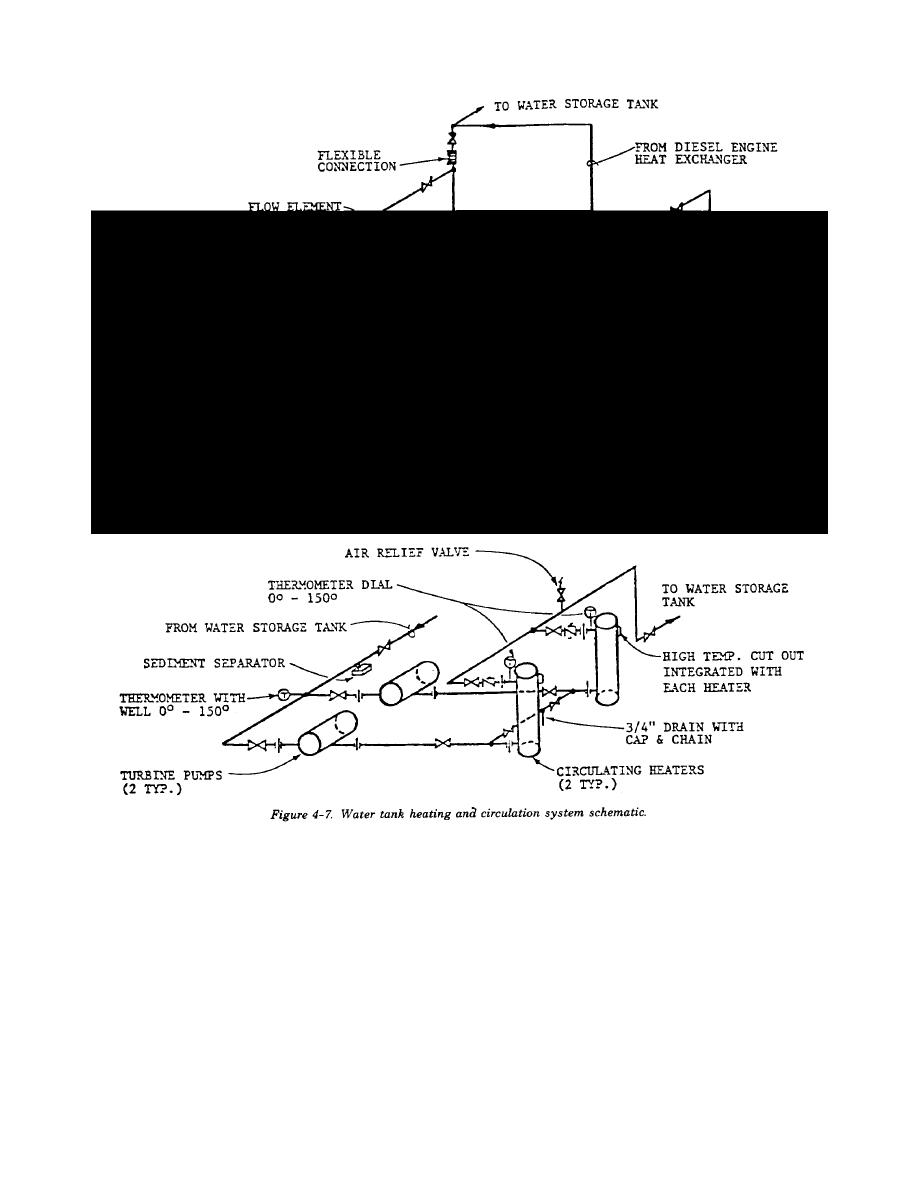

Fourth method: The fourth method of freeze prevention is to preheat the liquid before it

enters the pipeline. This method is suitable for both water and sewer lines. Circulation heaters, immersion

heaters, tank type water heaters, or recirculating coil (electric or glycol solution) type heaters may be used,

depending on the fluid and system type.

4-13

Previous Page

Previous Page