TM 5-852-5/AFR 88-19, Volume 5

maximum heat loss rate calculated in paragraph 12-

9e (134,904 BTU/yr LF pipe).

i. Determine the economical thickness of insula-

tion for an above-ground 6-inch-OD water main to

be located at Barrow, Alaska (temperature

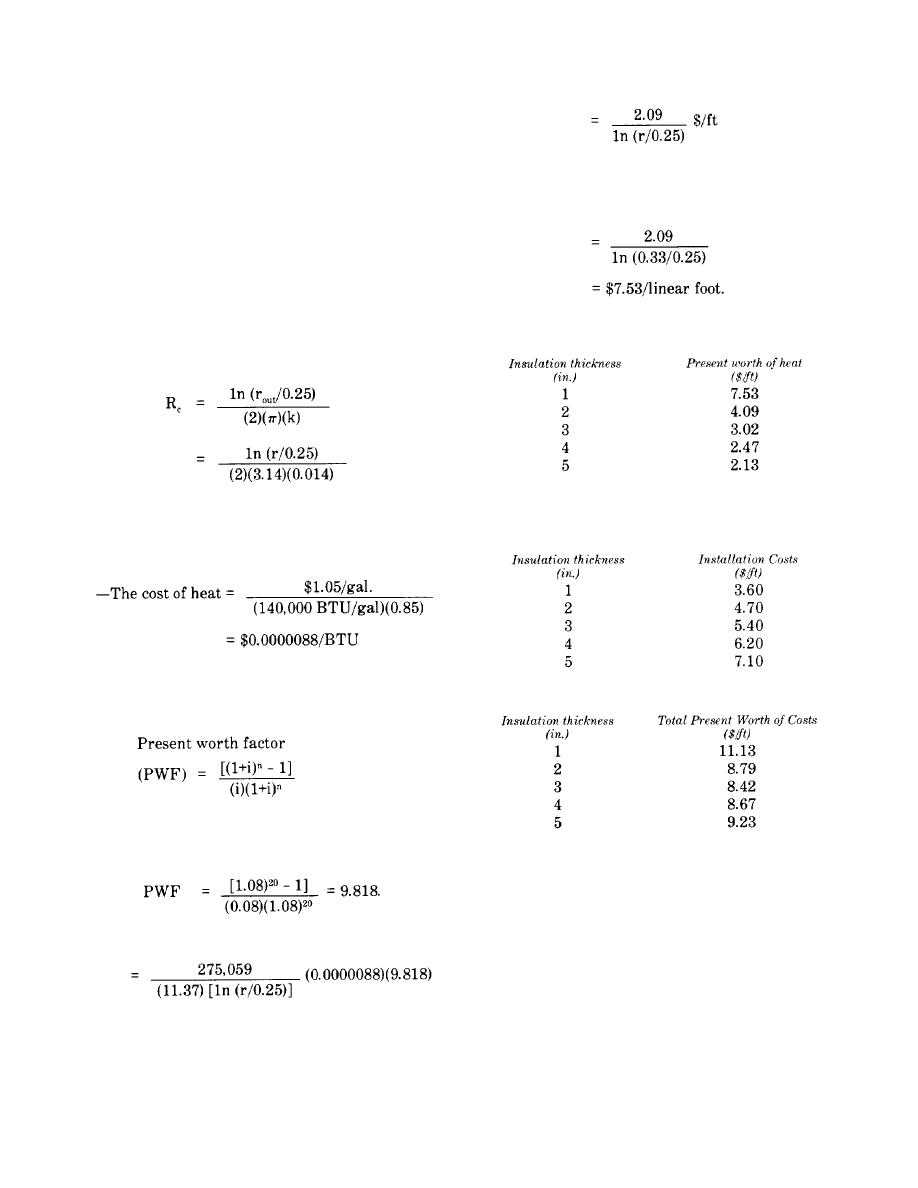

at an insulation thickness of 1 in., r = (1/12 in.) +

conditions as defined in paragraph 12-9f). Assume

(0.25 ft) = 0.33 ft. Therefore, the present worth of

fuel oil cost (140,000 BTU/gallon) at

||content||

.05/gallon,

heating costs

and an 85% efficient heating plant. Assumed

installed costs of polyurethane foam are tabulated

below for various available thicknesses. Thermal

for polyurethane is 0.014

BTU/fthrEF. Assume a 20-year design life at an

interest rate of 8%.

--Repeat calculations, and tabulate, for typical

--Neglecting air film and steel pipe material, the

insulation thickness:

combined thermal resistance is

--Installation costs for polyurethane insulation

= (11.37) [ln(r/0.25)

(assumed for this example only, obtain from

suppliers in actual case):

--The heating index for Barrow, Alaska, would

be 275,059EFhr (see example 12-9g).

--The economical thickness will have the lowest

total cost for construction plus the present worth

--Combining heating and construction costs give:

of the annual heating costs:

where i = interest rate (as a decimal)

n = design period

for i =0.8 and n = 2O

--Plot these results on arithmetic graph paper to

determine the lowest cost. Then select the available

nominal thickness of insulation that is closest to the

graphical value. In this case a 3-inch thickness

--Present worth of heating costs = heating

would be the most cost effective for the conditions

index/Rc x (PWF)(cost of heat)

assumed.

12-22

Previous Page

Previous Page