TM 5-852-4/AFM 88-19, Chap. 4

U. S. Army Corps of Engineers

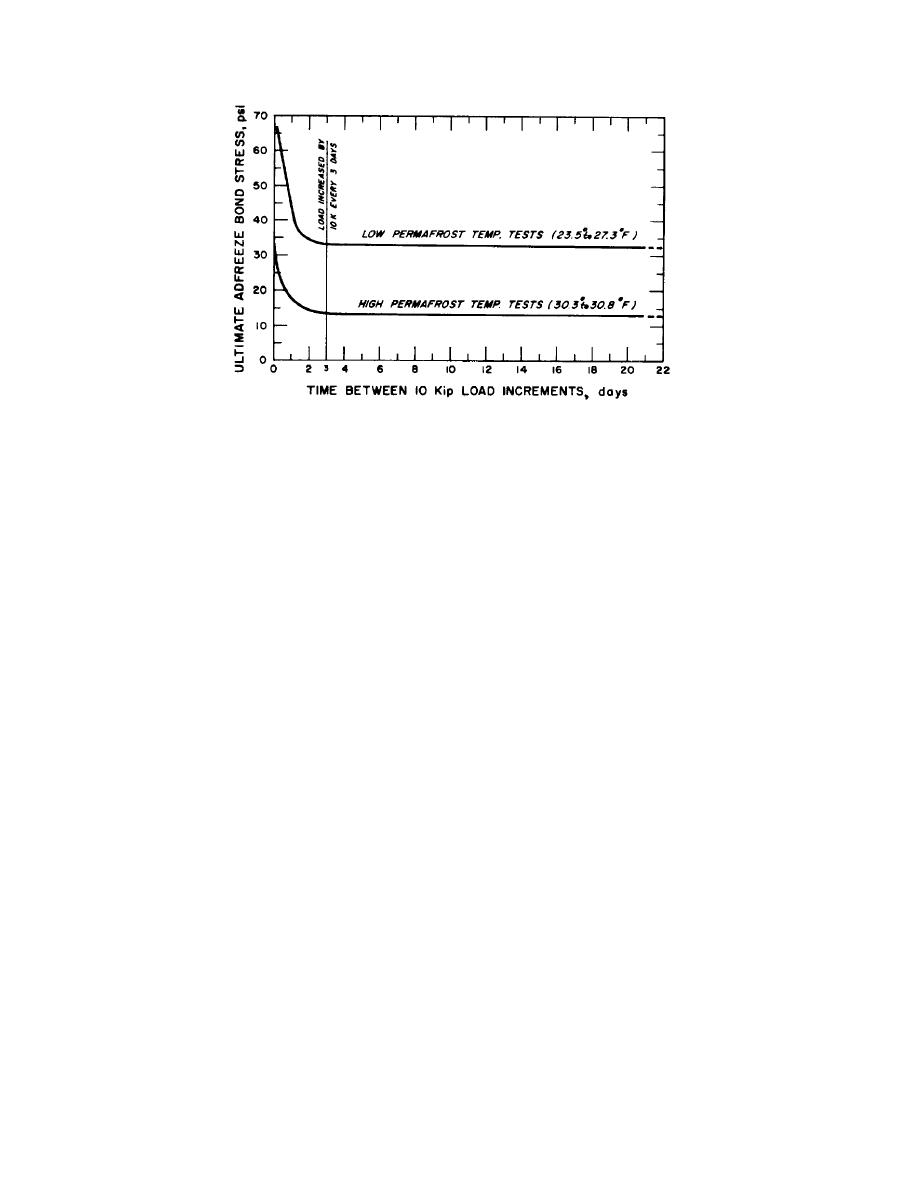

Figure 4-85. Effect of rate of loading and temperature on adfreeze strength of steel pipe piles134. Curves based on tests of

6 inch steel pipe piles installed in augered holes backfilled with silt-water slurry at Fairbanks, Alaska. Embedment of piles

in permafrost varied from 10.9 to 12.0 ft.

were only held one day. However, that obtained in the

made with equivalent end bearing piles. Such analyses

test shown in figure 4-84 with each increment held at

give indications of the length of pile actively supporting

least four days requires no correction. A continuous

load and assist in recognition of failure situations.

record of deformations should be obtained under each

(8) A value of failure or ultimate load

load increment and continuing deformation rates at ends

should be determined from the load test results. A

of the increment periods should be plotted against load

number of common criteria for selection of failure load

5

are listed in TM 5-818-1/AFM 88-3, Chapter 7 . The

to assist in determination of the load level at which

most appropriate of these for tests in frozen ground is

excessive creep deformations begin. However, it should

that which defines the failure or ultimate load as the load

be kept in mind that stress redistribution along the length

indicated by intersection of tangent lines drawn through

of the pile under an increment of load may continue far

the initial, flatter portion of the load-deformation curve

beyond a period of even three days and that such

and through the steeper part of the same curve.

readings should not be assumed to quantitatively

Adjustment to the critical design temperature should then

represent creep rates under long term steady load. The

be made if required, using the data shown in figure 4-82

load may be completely removed at intervals during the

and the allowable design load should be computed by

test and the rebound of the pile noted. The rebound of

application of a factor of safety as indicated in h below.

the pile after the maximum load had been released

(9) If the length of time required to perform

should be observed for at least 24 hours.

The

an exploratory load test as described is unacceptable, an

deformation of the pile after rebound (point E in fig. 4-

alternative approach is to perform simultaneously several

84) is known as the net or plastic deformation. The

verification pile load tests as described below, with load

algebraic difference between the total deformation and

values selected so as to positively bracket and establish

the net settlement (difference in deflection between C

the acceptable design load.

and E in fig. 4-84) is known as the elastic deformation of

(10) In verification pile load tests the pile

the pile and soil. The net or plastic deformation of piles

in permafrost rarely exceeds 0.50 inch before complete

may be loaded to the design load in a single increment

failure of the pile.

and then to 2 1/2 times the design load in a second

(7) As shown in figure 4-84, analysis is

increment, all other requirements remaining the same as

aided by comparing the observed deformations with the

for an ex-

computed pile shortening. Comparison may also be

4-142

Previous Page

Previous Page