TM 5-852-4/AFM 88-19, Chap. 4

U. S. Army Corps of Engineers

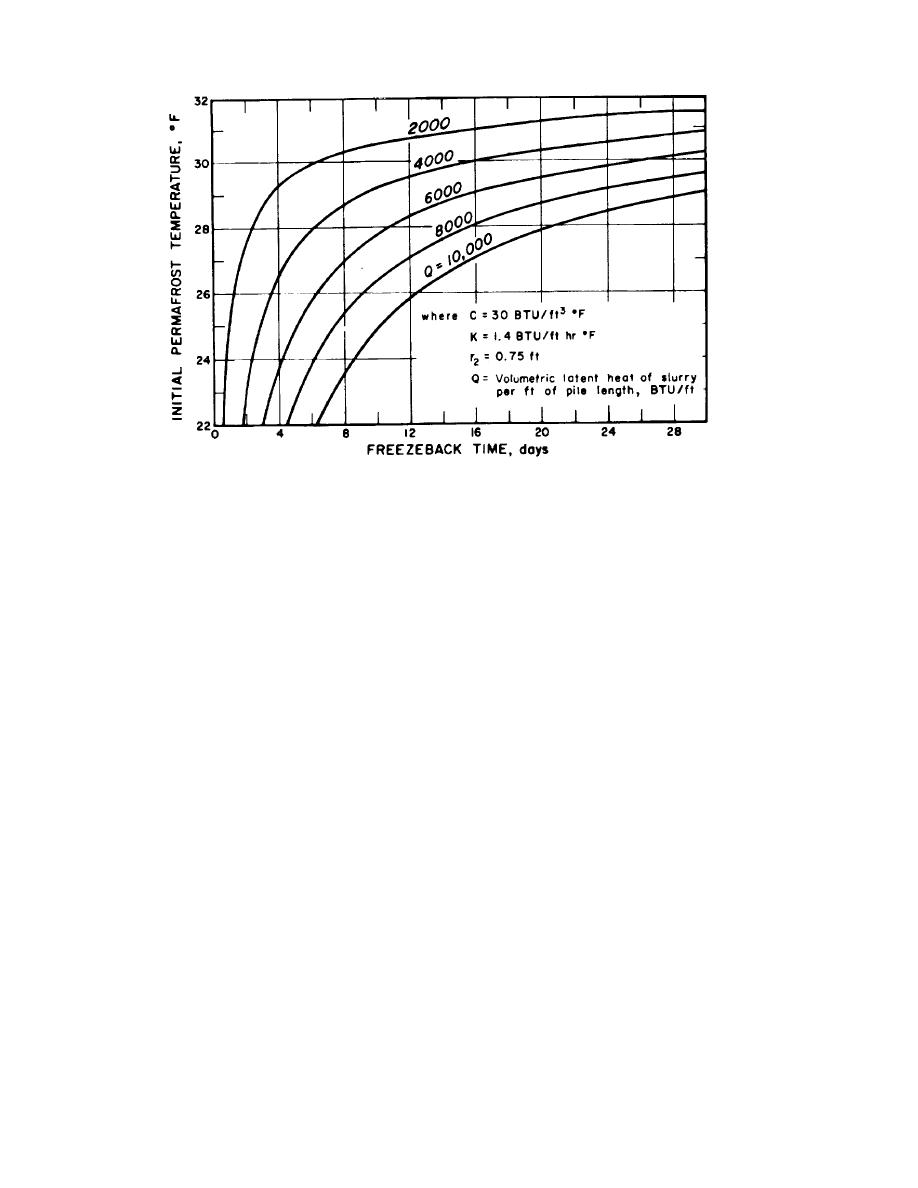

Figure 4-72. Specific solution of slurry freezeback rate134.

assume the slurry heat to be conducted only in a

be used to accomplish the desired freezing of the

horizontal radial direction. The actual heat paths during

backfill. The artificial freezing may be accomplished by

summer and winter are approximately as shown in figure

circulation of refrigerating fluid through longitudinal or

4-73. However, while freezeback time may be increased

spiral steel or copper tubing attached to the pile, or by

or decreased by deviations of heat flow from the

use of thermal piles as described in e below. Brine or

horizontal, and adjustment of the assumed "effective"

glycol solutions and ambient air have all been used as

temperature of the permafrost may sometimes be

the circulating fluid. However, the use of propane or

necessary to allow for this effect, the increase in

other refrigerants of similar characteristics has been

freezeback time which may be caused by proximity

found to be the most efficient and economical. Propane

between adjacent piles is a more dominant consideration

has the disadvantage of flammability. The refrigerant

((4) below), everything else being equal.

may be circulated through piles either individually or in

(3) Artificial freezeback.

series, using a portable compressor, as shown in figures

(a) When ground temperatures are

4-74 and 4-75. The size of the compressor depends on

the number of piles to be frozen and the amount of heat

too warm or the amount of heat introduced is too great to

to be removed from the slurry. Pipe size, exposure area

accomplish natural freezeback of slurry within the

per foot of pile length, and rate of circulation are other

planned construction period, artificial refrigeration must

4-118

Previous Page

Previous Page