| Tweet |

Custom Search

|

|

|

||

MIL-HDBK-1003/13A

Since field labor is expensive, the collector housing should be designed such

that the collector units can be quickly secured in place and connected to the

external piping. Provisions should also be made for easy replacement of

broken glass covers. The absorber plate should be mounted so as to be

thermally isolated as much as possible from the housing.

2.1.6 Collector gaskets and sealants. Gaskets and sealants must be

carefully selected if a collector is to have a long life. Generally, the

housing and the glazing have different rates of thermal expansion. Gaskets

and sealants form the flexible interface between the two components and seal

out moisture and other contaminants; if they fail, moisture will fog the

glazing and may possibly damage the absorber coating and the insulation.

These problems can drastically reduce the thermal performance of the

collector.

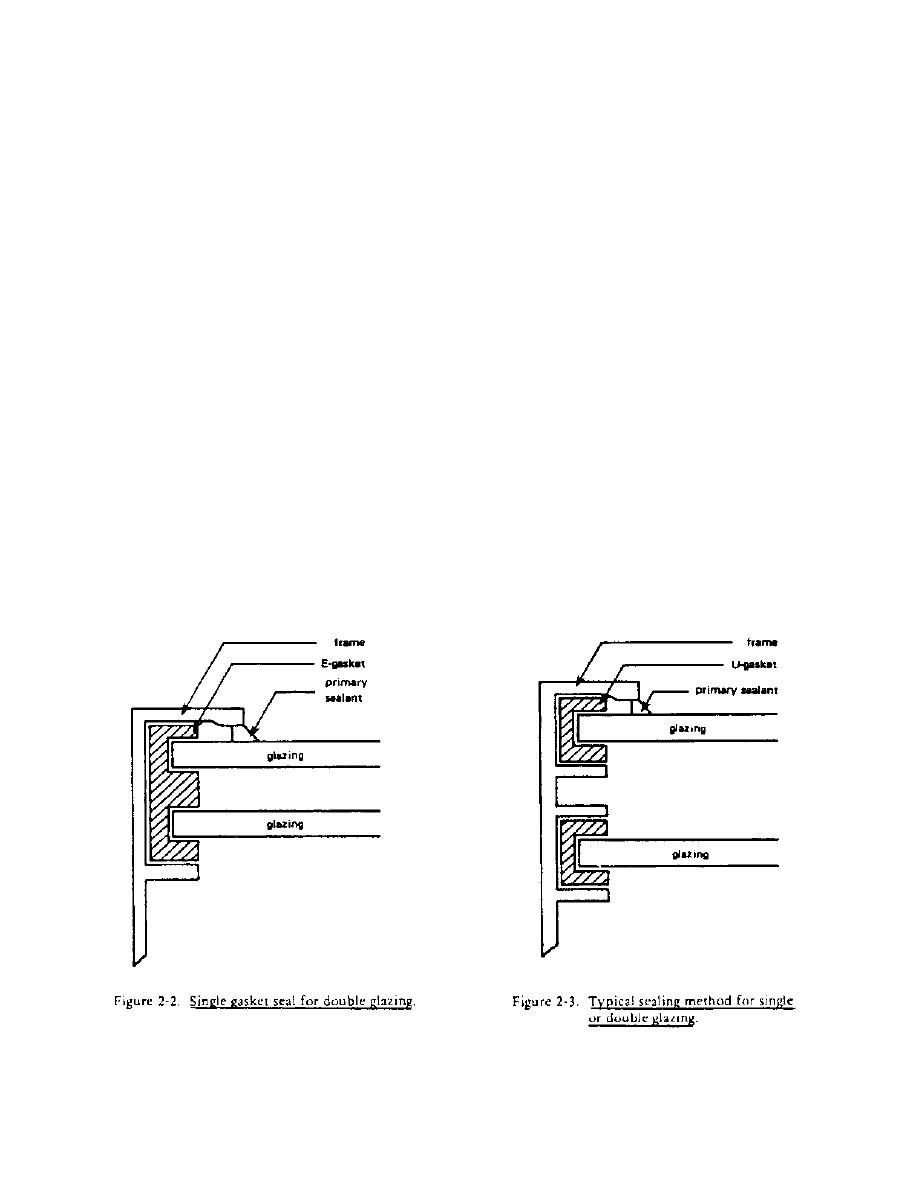

Two suitable sealing methods are shown in Figures 2-2 and 2-3 (Montgomery,

1978). The gaskets provide flexible support and the primary weather sealant

insures against moisture leakage. Desiccants are sometimes placed between

the two glazings to absorb any moisture that may remain after cover

installation. When selecting collector gaskets and sealants, certain

material requirements must be kept in mind. The gaskets and seals must:

a.

Withstand significant expansion and contraction without destruction.

b.

Adhere effectively to all surfaces.

c.

Resist ultraviolet degradation.

d.

Resist outdoor weathering.

e.

Not harden or become brittle.

f.

Withstand temperature cycling from -30 deg. to 400 deg. F.

g.

Not outgas at high temperatures.

24

|

|

|

|

||